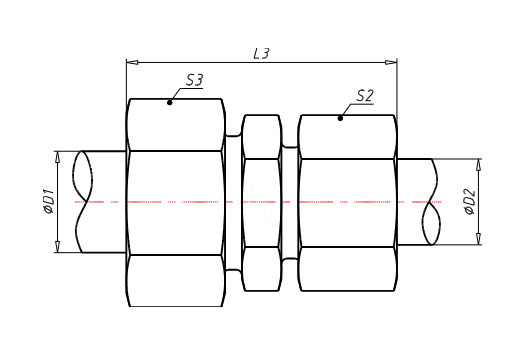

Straight Reducing Couplings

Straight Reducing Couplings is a type of pipe fitting connection method that can connect two sections of pipelines, changing the diameter of the pipeline from one size to another. It can also be used to connect pipelines with different connection methods, changing the pipeline from different connection methods to the same connection method, thus meeting the requirements of industrial pipelines in different situations.

Overview

Application:

Card sleeve direct connector is a widely used connecting component in oil, gas, and general corrosive medium pipeline systems. This type of joint adopts a sleeve type tapered thread design, which has the characteristics of simple connection, firm, and good sealing. It does not require welding and is suitable for high-pressure and vibration resistant applications, especially for complex pipeline connections that do not allow welding.

Features:

Widely applicable: Suitable for different liquid or gas pipelines, can support different pressure and temperature ranges.

Convenient maintenance: The straight through variable diameter joint is easy to install, disassemble, and maintain, which can greatly save time and labor costs.

Increasing flow rate: By changing the diameter of the pipeline, the flow rate of liquid or gas can be increased, thereby increasing the flow rate of the pipeline.

Strong universality: The straight through variable diameter joint has a variable diameter function and can connect pipes of different specifications, improving the universality of the joint.

Good sealing performance: Through threaded connection, reliable sealing performance can be provided, effectively preventing gas or liquid leakage.

Strong corrosion resistance: Made of materials with strong corrosion resistance, it can resist the erosion of most acids, alkalis, solvents, and chemicals.

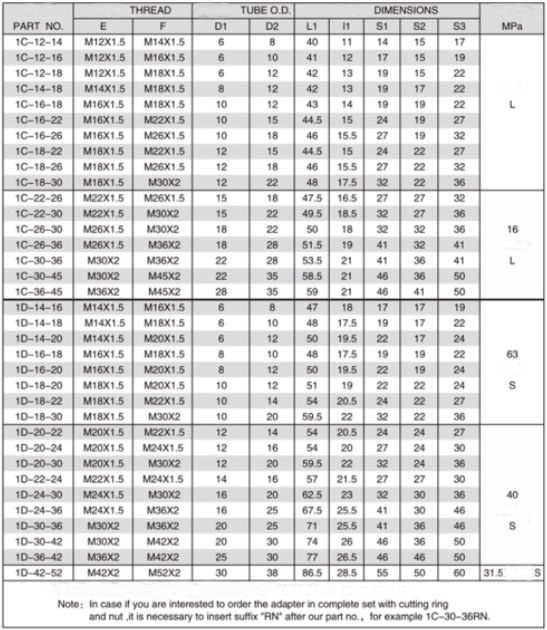

Basic Parameters: