Stainless Steel Wire Rope

HI-SEA MARINE provides premium quality 316 stainless steel wire ropes, perfect for a wide range of applications requiring superior corrosion resistance and strength. Our wire ropes are manufactured with precision.We supply a variety of specifications of stainless steel cable at types 316, 304, and coated stainless steel cable. Our Marine grade stainless steel wire rope can be deployed in marine oil and gas facilities and ocean shipping etc.

Stainless steel wire rope is made of high quality AISI304, AISI316 and other grades of stainless steel. It has excellent corrosion resistance, high temperature and low temperature resistance. After low temperature treatment, the wire rope can achieve higher strength. It is widely used in marine industry, petrochemical industry, aviation, automobile, fishery, precision instruments and building decoration and other industries.

Overview

Overview:

Material: AISI 304, AISI 316, and more.

Strength grade(N/mm2): 1570, 1770, 1870,1960

Core: metal core, WSC or IWRC.

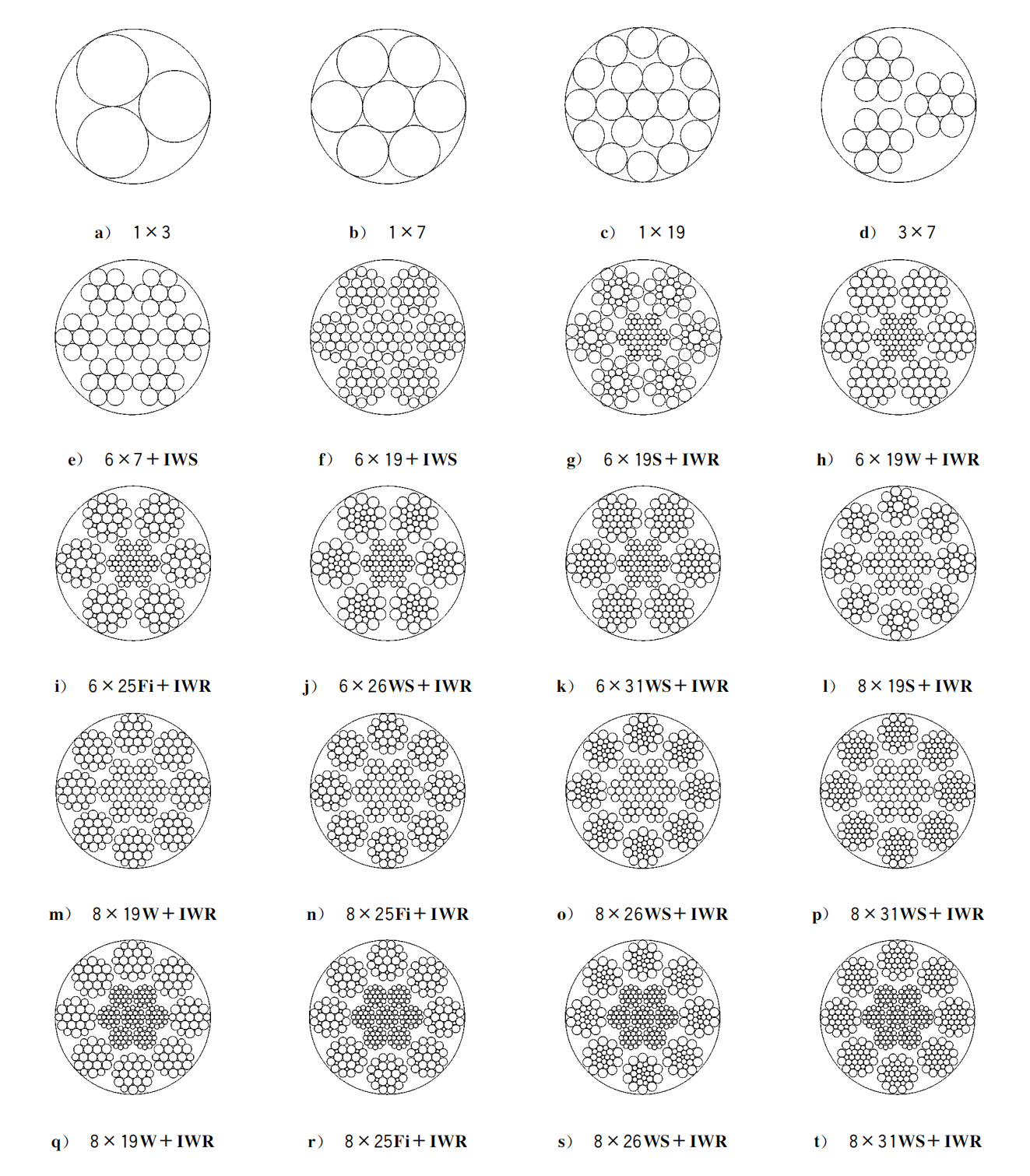

Typical construction class:1×3, 1×7, 1×19, 3×7, 6×7, 6×19(a), 6×19(b), 8×19

Stainless steel typical cross-sections:

Technology:

1. wire rod. Choiceness coiled raw material for the production of steel wires.

2. Pickling & surface treatment. Process removing rust and scale form the suface of the wire rod and coating a thin film.

3. Drawing. The most fundamental process in wire manufacturing where the wire diameter is reduced and the wire is elongated.

4. Patenting. Heating process that forms a fine homogeneous structure known as pearlite.

5. Plating. Process that thinly coats the wire with other metal to prevent corrosion and achieve a smooth and uniform surface.

6. Stranding & closing. The final process that twists several high strength wires and strands to combine the final wire rope product that is both strong and flexible.