Stainless Steel Safety Valve

Performance and Application Features

.Versatility: Suitable for a vast range of media: steam, air, gases, hot water, chemicals, corrosive fluids, and cryogenic (low-temp) services.

.Leak-Tightness: Provides excellent sealing before reaching the set pressure, minimizing product or energy loss.

.Repeatable Performance: Designed to perform its open-close cycle reliably and consistently over many cycles, with minimal deviation in set pressure.

Overview

Core Functional Features (Why They Are "Safety" Valves)

Automatic Pressure Relief: The primary function. It opens automatically when the system pressure exceeds a pre-set set pressure, preventing catastrophic failure.

Precise Set Pressure: Engineered and calibrated to open at a very specific pressure. This setting is tamper-resistant in certified valves.

Full-Lift or Pop Action: Most safety valves open rapidly ("pop") to their full lift position to achieve maximum flow capacity and quickly reduce pressure.

Re-sealing (Blowdown): After relieving pressure, they must re-close tightly at a pressure (the reseat pressure) lower than the set pressure. This "blowdown" difference ensures stability and prevents chattering.

Overpressure Capacity: Certified valves (ASME, PED) are designed to handle flows that can reach 110% of the maximum allowable working pressure (MAWP) without further pressure rise.

Material and Construction Features (Why "Stainless Steel")

Corrosion Resistance: The most critical advantage. Stainless steel (typically grades 304, 316, 17-4PH) resists rust and corrosion from water, steam, chemicals, acidic/alkaline environments, and marine atmospheres.

High-Temperature Strength: Maintains mechanical integrity and creep resistance at much higher temperatures than materials like brass or carbon steel.

Hygienic & Cleanable: Non-porous, smooth surface is ideal for sanitary applications (food & beverage, pharmaceuticals, biotech). Can be electropolished for easy cleaning and sterilization (CIP/SIP).

Durability & Longevity: Excellent resistance to wear, pitting, and galling, leading to a longer service life in harsh conditions.

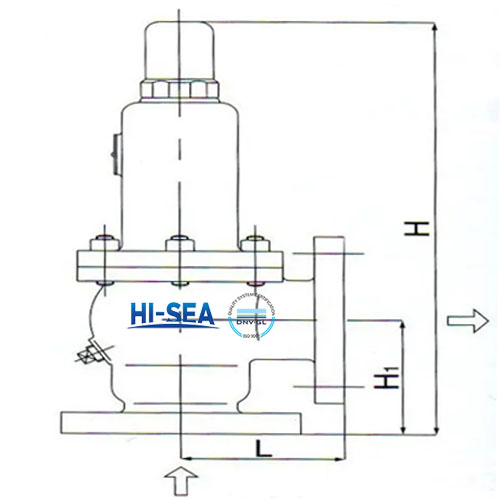

Drawing:

Picture: