Stainless Steel Globe Valves DIN

Stainless Steel Globe Valves they are commonly used in marine and industries such as sea water, fresh water, oil and gas, petrochemical, chemical processing, power generation, water treatment.

Stainless steel globe valves feature a short opening and closing action, stable sealing performance, and strong corrosion resistance.

Overview

Material Durability: Made from stainless steel, these valves offer excellent resistance to corrosion and rust, making them suitable for harsh or corrosive environments, including chemical processing and marine applications.

Flow Control: Globe valves are designed for throttling and regulating flow, allowing for precise control. The disc moves perpendicular to the seat, which enables good flow regulation and shut-off capabilities.

Pressure and Temperature Resistance: Stainless steel globe valves handle high-pressure and high-temperature conditions effectively, with some models rated for up to 1500 PSI or more.

Ease of Maintenance: Their straightforward design makes maintenance relatively simple, and many models allow in-line maintenance without the need to remove the valve from the piping system.

Applications: Ideal for use in industries where flow control is critical, such as water treatment, oil and gas, chemical processing, and marine systems.

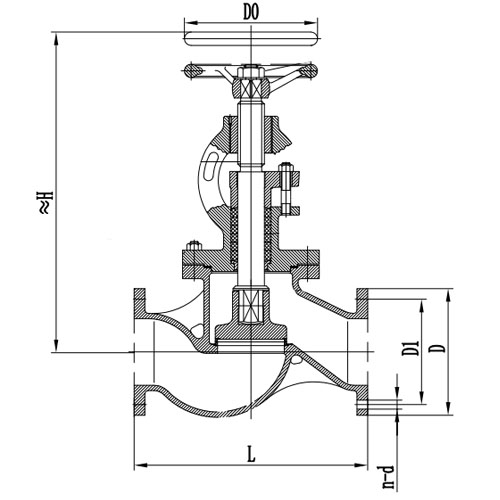

Drawing:

Image of product:

MAIN DIMENSIONS | |||||||||

Size | L | D | C | No. | h | t | H | D2 | Kg |

50 | 210 | 130 | 105 | 4 | 15 | 16 | 270 | 160 | 14.7 |

65 | 250 | 155 | 130 | 4 | 15 | 18 | 300 | 180 | 21.3 |

80 | 280 | 180 | 145 | 4 | 19 | 18 | 310 | 180 | 27.7 |

100 | 340 | 200 | 165 | 8 | 19 | 20 | 360 | 224 | 40.8 |

125 | 410 | 235 | 200 | 8 | 19 | 20 | 390 | 250 | 57.6 |

150 | 480 | 265 | 230 | 8 | 19 | 22 | 445 | 280 | 80.3 |

200 | 570 | 320 | 280 | 8 | 23 | 24 | 530 | 315 | 139 |

250 | 740 | 385 | 345 | 12 | 23 | 26 | 650 | 355 | 216 |

300 | 840 | 430 | 390 | 12 | 23 | 28 | 740 | 400 | 346 |

350 | 940 | 480 | 435 | 12 | 25 | 30 | 840 | 500 | 418 |

400 | 1050 | 540 | 495 | 16 | 25 | 30 | 940 | 630 | 600 |