Stainless Steel Check Valve

Stainless steel check valves find applications in various industries including oil and gas, petrochemical, chemical processing, water treatment, HVAC (Heating, Ventilation, and Air Conditioning), and plumbing. They are suitable for environments where corrosion resistance, durability, and high performance are required.

Overview

Material:

As the name suggests, stainless steel check valves are primarily made of stainless steel. Stainless steel is chosen for its durability, resistance to corrosion, and ability to withstand high temperatures and pressures. The specific grade of stainless steel may vary depending on the application and environmental factors.

Function:

The primary function of a check valve is to allow fluid or gas to flow in one direction while preventing reverse flow. When the flow pressure exceeds the pressure holding the valve closed, the disc or flap opens, allowing fluid or gas to pass through. When the flow pressure decreases or reverses, the disc closes under its own weight or with the assistance of a spring, preventing backflow.

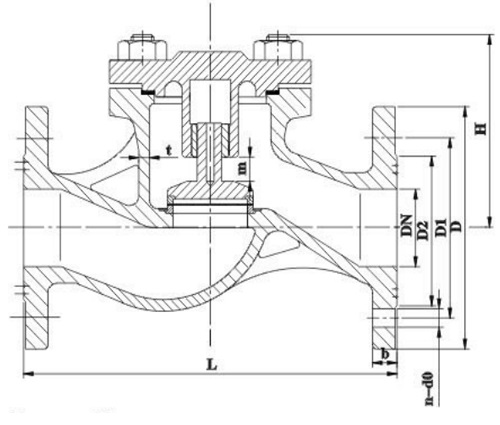

Drawing:

Elementary Dimensions | |||||||||||||||||

PN (Mpa) | DN (mm) | Frame dimension | Thickness | Flange | bolt | Lift Range | Weight kg | ||||||||||

I | J | H = | Hi | ||||||||||||||

A | B | A | B | B | D | Di | D2 | do | b | n | Th. | A | B | ||||

1.0 | 65 | 290 | 115 | 123 | 94 | 115 | 6 | 155 | 123 | 104 | 15 | 14 | 6 | M14 | 19 | 122 | 11.3 |

80 | 310 | 125 | 139 | 104 | 125 | 170 | 138 | 118 | 8 | 23 | 164 | 14.3 | |||||

100 | 350 | 150 | 160 | 117 | 135 | 190 | 158 | 138 | 28 | 24.6 | 22.7 | ||||||

125 | 400 | 175 | 185 | 129 | 155 | 7 | 215 | 183 | 164 | 10 | 35 | 37 | 30.4 | ||||

1.6 | 197 | 143 | 225 | 187 | 168 | 17 | 17 | M16 | 45.8 | 40.0 | |||||||

2.5 | 20 | 150 | 75 | 79 | 66 | 75 | 5 | 95 | 68 | 48 | 13 | 12 | 4 | M12 | 6 | 3.6 | 3.5 |

25 | 160 | 80 | 80 | 67 | 80 | 105 | 73 | 56 | 13 | 7 | 43 | 4.1 | |||||

32 | 180 | 85 | 85 | 68 | 85 | 115 | 83 | 64 | 15 | 6 | M14 | 9 | 5.0 | 4.8 | |||

40 | 200 | 90 | 88 | 76 | 90 | 125 | 93 | 74 | 14 | 12 | 63 | 6.0 | |||||

50 | 230 | 95 | 109 | 85 | 95 | 6 | 135 | 103 | 84 | 15 | 8.6 | 8.2 | |||||

65 | 290 | 115 | 123 | 94 | 115 | 7 | 170 | 132 | 110 | 17 | 17 | 8 | M16 | 19 | 133 | 11.5 | |

80 | 310 | 125 | 150 | 110 | 125 | 8 | 185 | 147 | 126 | 19 | 23 | 19.8 | 17.3 | ||||

100 | 350 | 150 | 155 | 118 | 135 | 205 | 167 | 146 | 10 | 28 | 303 | 25.7 | |||||