Solid Welding Neck Flange

Solid Welding Neck Flange is a flange which connects the steel pipe, pipe fittings, etc. into the flange and the equipment or pipeline through fillet weld. The sealing surface of Solid Welding Neck Flange is in the form of RF, FM, M, T, G, FF. The diameter range of Solid Welding Neck Flange is from DN10 to DN600, and the sealing surface is in the form of M, T, G, FF. Solid Welding Neck Flange has a range of diameters from DN10 to DN600.

Overview

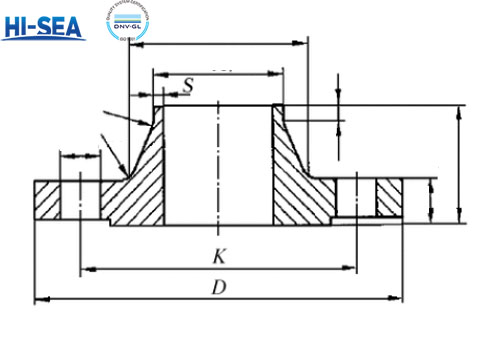

Structure:

Neck flanges are generally composed of flange body, gasket, neck and bolts. Among them, the neck is an important part of connecting the pipe and flange, which is a section of curved pipe. When installing, it needs to be inserted into the inside of the flange body in accordance with the correct angle and position, and the nut should be tightened well to achieve the effect of close connection.

The curved connection part of the neck flange can enhance the stability of the connection point and prevent the pipe from cracking or leaking

Due to the special structural design, the neck flange can be easily connected with the pipeline and is more stable, which shortens the installation time

Neck flanges have high corrosion resistance and high temperature resistance after connection, and have a long service life.

Drawing:

Picture:

DN | Standard ISO | d5 | D | b | k | h1 | d3 | s | r | h2 | d4 | f | Amount | d2 | Weight |

10 | 17.2 | 17.70 | 90 | 14 | 60 | 35 | 28 | 1.8 | 4 | 6 | 40 | 2 | 4 | 14 | 0.58 |

15 | 21.3 | 22.00 | 95 | 14 | 65 | 35 | 32 | 2.0 | 4 | 6 | 45 | 2 | 4 | 14 | 0.65 |

20 | 26.9 | 27.60 | 105 | 16 | 75 | 38 | 40 | 2.3 | 4 | 6 | 58 | 2 | 4 | 14 | 0.95 |

... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... |

400 | 406.4 | 423.7 | 565 | 26 | 515 | 72 | 440 | 7.1 | 12 | 16 | 482 | 4 | 16 | 26 | 26.27 |

500 | 508 | 513.6 | 670 | 26 | 620 | 75 | 542 | 7.1 | 12 | 16 | 585 | 4 | 16 | 26 | 38.27 |

600 | 600 | 616.5 | 780 | 28 | 725 | 80 | 642 | 7.1 | 12 | 18 | 685 | 5 | 20 | 30 | 46.56 |