Solid Slip On Flange

Slip-on flanges are a form of flange connection which usually consists of a flange, sleeve and casing with good sealing and anti-dislodgement properties. When installing slip-on flanges, it is necessary to dismantle the sleeve first and set it directly into the pipe, and then fix the sleeve and flange combination on the pipe. This kind of connection makes the slip-on flange more solid and better sealing, which is suitable for pipelines subject to extreme environments such as high pressure, high temperature and corrosion.

Overview

Advantages:

Slip-on flanges are suitable for pipeline connection under high pressure, high temperature, high viscosity, easy crystallization and other working conditions, and are commonly used in pipeline systems in petroleum, chemical, metallurgy, electric power and other fields.

Slip-on flanges are suitable for a variety of pipe connections, including cast iron pipe, steel pipe, plastic pipe, etc., which can effectively reduce the limitations of pipe connection methods and improve its scope of application and flexibility.

Slip-on flanges are made of high-quality materials, which can effectively improve their service life, especially under the conditions of high load, high temperature and high pressure, the service life of slip-on flanges is longer than that of traditional connection methods.

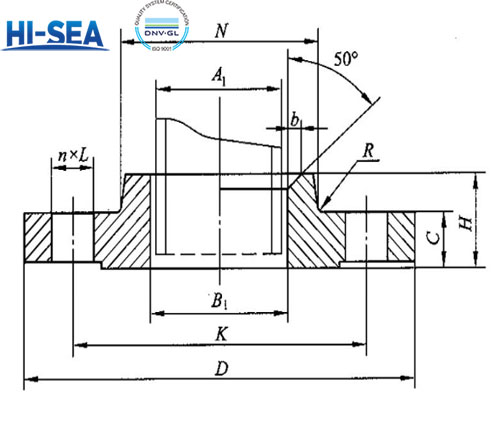

Drawing:

Picture:

DN | Flange Outer diameter | Joint Size | Flange Size | Weight | |||||||

A | B | D | K | L | n | Th | C | A | B | Kg | |

10 | 17.2 | 14 | 90 | 60 | 14 | 4 | M12 | 14 | 18 | 15 | 0.61 |

15 | 21.3 | 18 | 95 | 65 | 14 | 4 | M12 | 14 | 22 | 19 | 0.68 |

20 | 26.9 | 25 | 105 | 75 | 14 | 4 | M12 | 16 | 27.5 | 26 | 0.94 |

... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... |

450 | 457 | 480 | 615 | 565 | 26 | 20 | M24 | 35 | 462 | 485 | 27.9 |

500 | 508 | 530 | 670 | 620 | 26 | 20 | M24 | 38 | 513.5 | 535 | 34.9 |

600 | 610 | 630 | 780 | 725 | 30 | 20 | M27 | 42 | 616.5 | 636 | 48.1 |