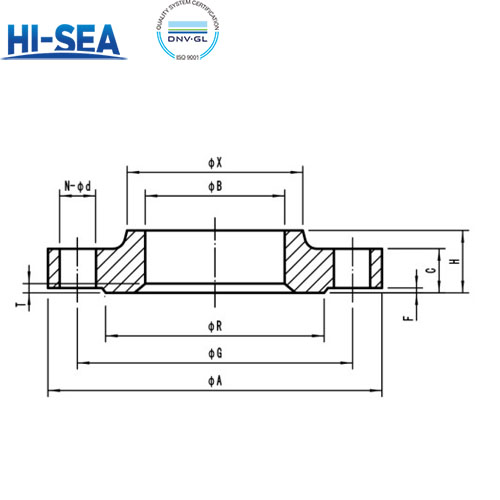

Socket Welding Sliding Flange

Socket welding sliding flange is a type of flange used for pipeline connection, combining the features of socket welding and sliding flange, similar to sliding flange in appearance, but the hole is countersunk, widely used in occasions requiring frequent thermal expansion and contraction.

Overview

Application

Petrochemical industry

Power industry

Pharmaceutical industry

Instrumentation field

HVAC system

Shipbuilding industry

Vessel and pipe connections

Advantages

High connection strength: High strength of the welded parts, able to withstand high pressure.

Good sealing: Ensure the sealing of piping connections and reduce the risk of leakage.

Compact structure: occupies little space, suitable for use in occasions with limited space.

Wide range of application: applicable to a variety of materials and specifications of the pipeline connection.

Good pressure resistance: the connection is firm and can withstand liquid or gas pipeline connections under high pressure.

Outside diameter | DIN 86033 | ||||||||||||

Pn10 | |||||||||||||

θD | θA | H | C | θX | θR | θB | F | T | Drilling | Theo. | |||

0G | N | θd | we1ght | ||||||||||

nominal | actual | mm | mm | mm | mm | m | mm | mm | mm | mm | b01t | m | Kg/ piece |

inch | mm | h01es | |||||||||||

0.375 | 16 | 90 | 18 | 12 | 26 | 40 | 16.2 | 2 | Not | 60 | 4 | 14 | 0.52 |

0.5 | 20 | 95 | 18 | 12 | 30 | 45 | 20.2 | 2 | 65 | 4 | 14 | 0.57 | |

0.75 | 25 | 105 | 18 | 12 | 35 | 58 | 25.2 | 2 | 75 | 4 | 14 | 0.71 | |

1 | 30 | 115 | 18 | 12 | 40 | 68 | 30.2 | 2 | 85 | 4 | 14 | 0.86 | |

1.25 | 38 | 140 | 20 | 14 | 49 | 78 | 38.25 | 2 | 100 | 4 | 18 | 1.47 | |

1.5 | 44.5 | 150 | 20 | 14 | 56 | 88 | 44.75 | 3 | 110 | 4 | 18 | 1.6 | |

2 | 57 | 165 | 22 | 16 | 69 | 102 | 57.3 | 3 | 125 | 4 | 18 | 2.2 | |

2.5 | 76.1 | 185 | 22 | 16 | 88 | 122 | 76.3 | 3 | 145 | 4 | 18 | 2.66 | |

3 | 88.9 | 200 | 24 | 18 | 101 | 138 | 89.4 | 3 | 160 | 8 | 18 | 3.32 | |

4 | 108 | 220 | 28 | 20 | 120 | 158 | 108.4 | 5 | 180 | 8 | 18 | 4.31 | |

5 | 133 | 250 | 28 | 20 | 146 | 188 | 133.65 | 5 | 210 | 8 | 18 | 5.37 | |

6 | 159 | 285 | 30 | 22 | 172 | 212 | 159.65 | 5 | 7 | 240 | 8 | 23 | 6.37 |

7 | 193.7 | 315 | 32 | 22 | 209 | 242 | 195 | 5 | 7 | 270 | 8 | 23 | 7.22 |

8 | 219.1 | 340 | 32 | 24 | 234 | 268 | 220 | 5 | 7 | 295 | 8 | 23 | 9.12 |

10 | 267 | 395 | 34 | 26 | 284 | 320 | 268.2 | 6 | 7 | 350 | 12 | 23 | 12.1 |

12 | 323.9 | 445 | 36 | 26 | 343 | 370 | 325.35 | 6 | 7 | 400 | 12 | 23 | 13.7 |

14 | 368 | 505 | 38 | 28 | 389 | 430 | 369.35 | 6 | 7 | 460 | 16 | 23 | 19.3 |

16 | 419.1 | 565 | 40 | 28 | 442 | 482 | 420.5 | 6 | 7 | 515 | 16 | 27 | 23.2 |

18 | 457.2 | 615 | 42 | 28 | 482 | 530 | 458.5 | 6 | 7 | 565 | 20 | 27 | 27.9 |

20 | 508 | 670 | 47 | 31 | 535 | 585 | 509.5 | 7 | 8 | 620 | 20 | 27 | 35 |

24 | 610 | 780 | 49 | 31 | 640 | 685 | 612 | 8 | 8 | 725 | 20 | 30 | 42.9 |