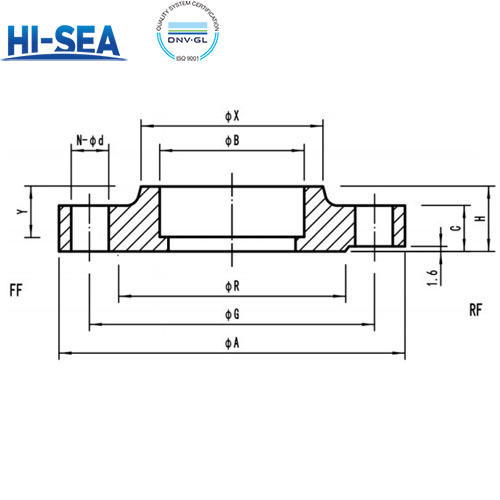

Socket Welding Flange

Socket welding flange is a kind of connecting parts used in industrial piping system, the main connection is to insert the end of the pipe into the flange ring step, welded at the end and outside of the pipe.

Overview

The component structure of socket weld flange includes flange body, sealing ring and bolt.

Common materials:

Carbon steel: such as ASTM A105, Q235, 16Mn and so on.

Stainless steel: such as ASTM A182 F304, 304L, F316, 316L and so on.

Alloy steel: such as ASTM A182 F1, F5a, F9, F11, etc.

Features:

Good sealing performance: it has good sealing performance and is suitable for the manufacture of connections under high pressure environment.

Simple welding process: no need to place any material between two metal parts, the welding process is relatively simple.

Firm connection: the connection effect is more solid, with higher load capacity.

Outside diameter | ANSIB16.5 | |||||||||||

150Lbs | ||||||||||||

θD | θA | H | C | θX | θR | θB | Y | Drilling | Theo. | |||

θG | N | θd | weight | |||||||||

nominal | actual | mm | mm | mm | mm | mm | mm | mm | mm | bolt | mm | Kg/ piece |

inch | mm | holes | ||||||||||

0.5 | 20 | 90 | 15.9 | 11.1 | 30.2 | 34.9 | 20.2 | 9.5 | 60.3 | 4 | 15.9 | 0.8 |

0.75 | 25 | 100 | 15.9 | 12.7 | 38.1 | 42.9 | 25.2 | 11.1 | 69.8 | 4 | 15.9 | 1.1 |

1 | 30 | 110 | 17.5 | 14.3 | 49.2 | 50.8 | 30.2 | 12.7 | 79.4 | 4 | 15.9 | 1.2 |

1.25 | 38 | 115 | 20.6 | 15.9 | 58.7 | 63.5 | 38.3 | 14.3 | 88.9 | 4 | 15.9 | 1.5 |

1.5 | 44.5 | 125 | 22.2 | 17.5 | 65.1 | 73 | 44.8 | 15.9 | 98.4 | 4 | 15.9 | 1.6 |

2 | 57 | 150 | 25.5 | 19.1 | 77.8 | 92.1 | 57.4 | 17.5 | 120.6 | 4 | 19 | 2.7 |

2.5 | 76.1 | 180 | 28.6 | 22.2 | 90.5 | 104.8 | 76.5 | 19 | 139.7 | 4 | 19 | 4.1 |

3 | 88.9 | 190 | 30.2 | 23.8 | 107.9 | 127 | 89.4 | 20.6 | 152.4 | 4 | 19 | 4.1 |

4 | 108 | 230 | 33.3 | 23.8 | 134.9 | 157.2 | 108.5 | 23.8 | 190.5 | 8 | 19 | 7 |

Outside diameter | ANSIB16.5 | |||||||||||

300Lbs | ||||||||||||

θD | θA | H | C | θX | θR | θB | Y | Drilling | Theo. | |||

θG | N | θd | weight | |||||||||

nominal | actual | mm | mm | mm | mm | mm | mm | mm | mm | bolt | mm | Kg/ piece |

inch | mm | holes | ||||||||||

0.5 | 20 | 95 | 22.2 | 14.3 | 38.1 | 34.9 | 20.2 | 9.5 | 66.7 | 4 | 15.9 | 0.9 |

0.75 | 25 | 115 | 25.4 | 15.9 | 47.6 | 42.9 | 25.2 | 11.1 | 82.5 | 4 | 19 | 1.4 |

1 | 30 | 125 | 27 | 17.5 | 54 | 50.8 | 30.2 | 12.7 | 88.9 | 4 | 19 | 1.7 |

1.25 | 38 | 135 | 27 | 19 | 63.5 | 63.5 | 38.3 | 14.3 | 98.4 | 4 | 19 | 2 |

1.5 | 44.5 | 155 | 30.2 | 20.6 | 69.8 | 73 | 44.8 | 15.9 | 114.3 | 4 | 22.2 | 3 |

2 | 57 | 165 | 33.3 | 22.2 | 84.1 | 92.1 | 57.4 | 17.5 | 127 | 8 | 19 | 3.4 |

2.5 | 76.1 | 190 | 38.1 | 25.4 | 100 | 104.8 | 76.5 | 19 | 149.2 | 8 | 22.2 | 5.1 |

3 | 88.9 | 210 | 42.9 | 28.6 | 117.5 | 127 | 89.4 | 20.6 | 168.3 | 8 | 22.2 | 6.8 |

4 | 108 | 255 | 47.6 | 31.8 | 146 | 157.2 | 108.5 | 23.8 | 200 | 8 | 22.2 | 11.3 |