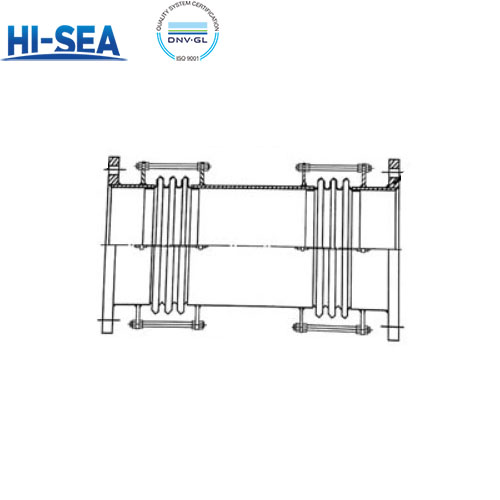

Small Rod Horizontal Type Expansion Joint

Small tie rod horizontal expansion joint is a kind of equipment used to compensate the displacement change caused by thermal expansion and contraction, vibration and other factors in pipeline system, small tie rod can not withstand the internal pressure thrust, mainly through the deformation of bellows to absorb displacement, when the pipeline expansion or contraction due to temperature change, the compensator can provide the necessary displacement compensation to protect the pipeline system from damage.

Overview

Advantages

(1) Freedom of compensation direction: the small tie rod transverse corrugated compensator can freely compensate transverse, axial and angular displacements, which makes it perform well in the compensation of displacements in many directions.

(2) Good stability: through the design of two-section bellows, the small-tie rod transverse corrugated compensator can absorb transverse displacement and axial displacement at the same time, with good stability and good compensation effect.

(3) Occupying small space: Due to its small external dimensions, it occupies small space and is especially suitable for compensation between places with narrow space or large equipment.

(4) Long service life: small tie rod transverse type compensator has a long service life, which effectively improves the reliability of the connection between pipes.

(5) Noise reduction and vibration damping: the use of deformation of the mechanical force of the heat transfer function, small tie rod transverse type compensator can also effectively reduce vibration and noise transmission.

(6) Wide range of application: suitable for complex geological conditions, settlement amplitude and pipeline operation in the pipeline damage caused by frequent hot and cold changes in the place.

(7) Low maintenance cost: designed with smooth inner wall, it has no effect on the flow rate and flow of medium, and it never rusts, which basically exempts the maintenance during the effective movement period.

Nominal Path DN mm | Bellows | Axial | Y0-Horizontal compensation(mm) | KY0-Lateral stiffness(N/mm) | Radial | Product Type | ||||||||||||

Effective Area A cm2 | Wave Number n | Compensation amount X0 ±mm | Stiffness Kθ0 N/mm | Total length L mm | ||||||||||||||

1500 | 2000 | 2500 | 3000 | 3500 | 4000 | |||||||||||||

Y0 | KY0 | Y0 | KY0 | Y0 | KY0 | Y0 | KY0 | Y0 | KY0 | Y0 | KY0 | |||||||

Design pressure Pd=1.0MPa (0.25kgf/cm2) Fatigue life [N]=1000 Design temperature t=20℃ | ||||||||||||||||||

100 | 154 | 8 4+4 | 22 | 348 | 162 | 3.3 | 247 | 1.5 | 332 | 0.84 | 308 | |||||||

150 | 299 | 34 | 504 | 109 | 9.2 | 166 | 4.2 | 223 | 2.4 | 359 | AXH | |||||||

200 | 531 | 58 | 746 | 115 | 26 | 179 | 12 | 244 | 6.5 | 439 | ||||||||

250 | 779 | 33 | 925 | 91 | 48 | 143 | 21 | 195 | 12 | 247 | 7.5 | 493 | ||||||

300 | 1075 | 42 | 768 | 96 | 57 | 152 | 25 | 209 | 14 | 266 | 8.7 | 545 | ||||||

350 | 1269 | 42 | 840 | 76 | 92 | 127 | 37 | 178 | 20 | 230 | 12 | 627 | ||||||

400 | 1619 | 41 | 958 | 67 | 134 | 111 | 54 | 155 | 29 | 200 | 18 | 676 | ||||||

450 | 2003 | 40 | 1074 | 59 | 185 | 98 | 74 | 138 | 40 | 177 | 25 | 728 | ||||||

500 | 2428 | 40 | 1190 | 53 | 249 | 89 | 100 | 124 | 53 | 160 | 33 | 779 | ||||||

600 | 3473 | 71 | 781 | 54 | 379 | 104 | 126 | 156 | 62 | 209 | 37 | 262 | 24 | 880 | AXHK | |||

700 | 4747 | 80 | 731 | 52 | 486 | 100 | 162 | 150 | 80 | 201 | 47 | 252 | 31 | 1150 | ||||

800 | 6046 | 79 | 792 | 46 | 671 | 88 | 224 | 132 | 110 | 176 | 65 | 221 | 43 | 1250 | ||||

900 | 7503 | 78 | 854 | 41 | 897 | 78 | 299 | 117 | 147 | 157 | 87 | 196 | 57 | 1350 | ||||

1000 | 9314 | 69 | 202 | 32 | 2637 | 62 | 879 | 92 | 432 | 123 | 256 | 155 | 169 | 1480 | ||||

1100 | 11103 | 68 | 2203 | 29 | 3425 | 56 | 1141 | 84 | 561 | 112 | 332 | 140 | 220 | 168 | 156 | 1580 | ||

1200 | 13060 | 68 | 2386 | 27 | 4359 | 51 | 1453 | 77 | 714 | 103 | 423 | 129 | 279 | 155 | 198 | 1680 | ||

1300 | 15153 | 67 | 2509 | 24 | 5451 | 47 | 1817 | 71 | 893 | 94 | 529 | 118 | 349 | 142 | 248 | 1780 | ||

1400 | 17413 | 67 | 2752 | 23 | 6709 | 44 | 2236 | 66 | 1100 | 88 | 651 | 110 | 430 | 133 | 305 | 1880 | ||

1500 | 19831 | 66 | 2956 | 21 | 8151 | 41 | 2716 | 61 | 1336 | 82 | 791 | 102 | 522 | 123 | 377 | 1980 | ||

Design pressure Pd=16MPa (16kgf/cm2) Fatigue life [N]=1000 Design temperature t=20℃ | ||||||||||||||||||

100 | 156 | 8 | 18.4 | 474 | 124 | 6.3 | 189 | 2.8 | 254 | 1.6 | 308 | AXH | ||||||

150 | 302 | 17.6 | 955 | 85 | 18 | 130 | 7.9 | 174 | 4.5 | 359 | ||||||||

200 | 535 | 31.6 | 746 | 106 | 26 | 166 | 12 | 226 | 6.5 | 439 | ||||||||

250 | 779 | 31 | 930 | 85 | 48 | 133 | 21 | 181 | 12 | 229 | 7.5 | 493 | ||||||

300 | 1081 | 33 | 1472 | 74 | 110 | 117 | 48 | 161 | 26 | 204 | 17 | 545 | ||||||

350 | 1275 | 23 | 1614 | 59 | 177 | 99 | 71 | 138 | 38 | 178 | 24 | 672 | ||||||

400 | 1625 | 32 | 1845 | 52 | 258 | 86 | 103 | 121 | 55 | 156 | 34 | 676 | ||||||

450 | 2011 | 32 | 2072 | 46 | 359 | 77 | 144 | 108 | 77 | 139 | 48 | 728 | ||||||

500 | 2437 | 31 | 2300 | 42 | 482 | 69 | 193 | 97 | 103 | 125 | 64 | 779 | ||||||

600 | 3484 | 55 | 1453 | 41 | 709 | 80 | 236 | 120 | 116 | 160 | 69 | 201 | 45 | 880 | AXHK | |||

700 | 4754 | 62 | 1328 | 40 | 884 | 77 | 295 | 116 | 145 | 155 | 86 | 194 | 57 | 1010 | ||||

800 | 6055 | 61 | 1462 | 35 | 1240 | 68 | 413 | 101 | 203 | 135 | 120 | 169 | 79 | 1110 | ||||

900 | 7512 | 60 | 1602 | 31 | 1685 | 60 | 526 | 90 | 276 | 120 | 164 | 150 | 108 | 1210 | ||||

1000 | 9314 | 64 | 2052 | 30 | 2676 | 57 | 892 | 86 | 439 | 115 | 260 | 144 | 172 | 1340 | ||||