Shipbuilding Deck Drain

Overview

Product requirements for Shipbuilding Deck Drain

1. The surface bite of the welding of the shipbuilding deck drain mouth should be less than 0.5mm, and defects such as stomata, edge failure to fuse and welding tumor are not allowed.

2. The steel parts of the shipbuilding deck drain must be galvanized, you can choose hot galvanized or cold galvanized, and the thickness of the zinc layer is not less than 35μm.

3. The welding of the leakage port of SB and SC shipbuilding deck drain should be firm, and there should be no leakage after the body is filled. The water seal test should also be done, and the valve opening and closing operation test should be done for SB and SC shipbuilding deck drain: After the water is filled to the level of the body, there should be no leakage.

4. The shipbuilding deck drain on the Marine deck is placed under the water pressure of 0.12 for 5 minutes, and the tightness of the water leakage body and the valve is checked.

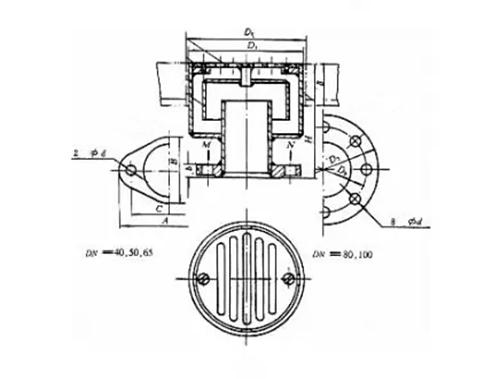

Drawing

Images of Shipbuilding Deck Drain