Shell and Tube Heat Exchanger

Shell and tube heat exchangers are the heat exchanger type with the widest application. Currently, most of the oil coolers, fresh water coolers, fuel heaters, condensers and so on on ships are of the shell and tube type.

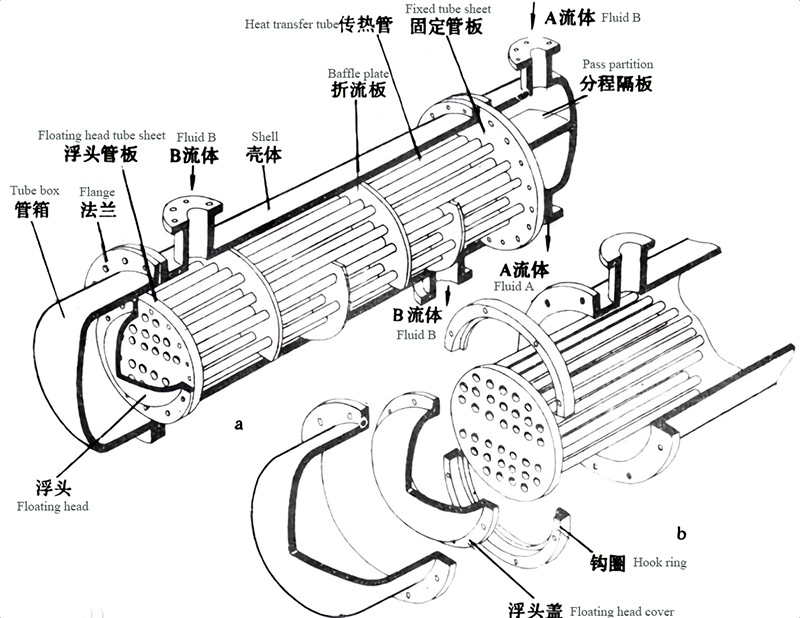

There are numerous structural forms of shell and tube heat exchangers, yet there are three fundamental types: fixed plate and tube type, U-shaped tube type and floating head type.

Overview

Shell and Tube Heat Exchanger Introduction

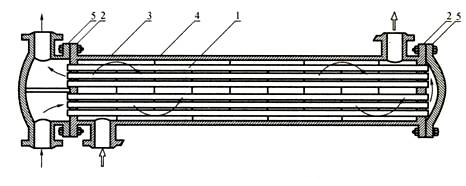

Fixed plate and tube heat exchanger

The picture presents a fixed plate and tube heat exchanger, which is mainly constituted by a shell 3, front and rear covers 5, and heat transfer tubes 1 fixed on the tube sheet 2. Two fluids for heat exchange, one flows through the heat transfer tube while the other flows through the shell. To increase the flow velocity and flow rate of the fluid in the housing, multiple transverse partitions 4 are arranged inside the housing. The flow conditions of the two fluids are shown in the figure.

The characteristic of the fixed plate tube heat exchanger is that the tube plates at both ends of the tube bundle are fixed to the shell. It has a simple structure and is easy to manufacture. However, as the tubes, tube sheets and shell are rigidly connected, when there is a relatively large temperature difference between the two fluids, due to uneven expansion among the shell, tube and tube sheet, leakage may occur at the connection. Thus, it can only be applied in occasions with a small temperature difference. Additionally, since the tube bundle cannot be pulled out from the housing, it is difficult to clean the outer wall of the tube.

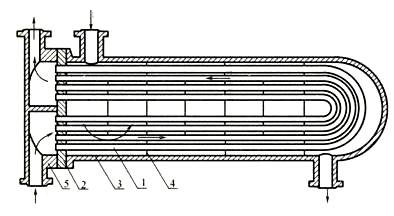

U-shaped tube heat exchanger

To overcome the shortcoming of leakage caused by uneven expansion, the straight pipe is replaced by a U-shaped tube, and the two nozzles are fixed on the same tube sheet, thereby forming a U-shaped tube heat exchanger as shown in the figure.

The characteristic of the U-tube heat exchanger is that the tube can expand freely within the shell, and the tube bundle can be withdrawn from the shell, which is convenient for cleaning the outer wall of the tube. However, the dirt on the inner wall of the tube is not easy to clean. In addition, the U-shaped tube is surrounded in layers. Yes, if the inner tube is damaged, it cannot be replaced.

U-shaped tube heat exchangers are suitable for occasions with a large temperature difference and relatively clean fluid in the tube, such as fuel heaters, fuel injector fresh water coolers, and so on.

Movable Tube Sheet heat exchanger

The movable tube sheet heat exchanger is an improvement upon the fixed plate and tube heat exchanger. If one end of the heat transfer tube is fixed to a movable tube sheet that is slightly smaller than the inner diameter of the shell, when the heat transfer tube bundle is heated and expands, the tube sheet can slide along the axial direction of the shell. To prevent mutual leakage of cold and hot fluids, packing is installed on the outer periphery of the movable tube sheet and compressed with a pressure ring.

Compared with fixed heat exchangers, movable tube sheet heat exchangers have two major advantages. Firstly, the movable tube sheet can slide within the shell, reducing the likelihood of leakage caused by uneven expansion. Secondly, the tube bundle can be withdrawn from the shell, making it easy to clean the outer wall of the tubes. Due to these advantages, the movable tube sheet heat exchanger has good adaptability to working fluids and can operate reliably under a large temperature difference. As a result, it has been widely used, mainly as the main engine oil cooler and main engine fresh water cooler.