Screw compressor

The screw air compressor is mainly composed of two screws (rotors) that mesh with each other. Through the rotation of the rotor, air is sucked in from the intake port and compressed towards the exhaust port along the teeth of the screw, thereby achieving the compression process of air. The compression process is divided into the following stages:

Inhalation process: Air enters the screw compression chamber through the intake valve.

Compression process: The air is gradually compressed and the pressure increases during the rotation of the rotor.

Exhaust process: High-pressure air is discharged through the exhaust valve and enters the air storage tank or is directly supplied to the gas equipment.

Overview

A screw air compressor is a widely used equipment in the shipbuilding and industrial fields, which provides a stable compressed air source through screw compressed air.

Main characteristics

A low-pressure screw compressor using reliable technology, with an exhaust pressure as low as 0.35mpa and a displacement of up to 6om */min, has the advantages of energy conservation and reliability, making it the preferred choice in the textile, glass, and pharmaceutical industries.

Adopting a box design, the structure is compact and easy to install.

Stable and long-lasting pressure, sufficient displacement, low exhaust temperature, low oil content, and stable performance.

Multiple safety protection design, balanced and reliable operation, and long maintenance cycle.

Always monitor the working status, the intelligent control system fully meets the continuous and uninterrupted operation under unmanned supervision, and adopts a multi machine joint control setting to automatically turn on or off the compressor according to the exhaust volume.

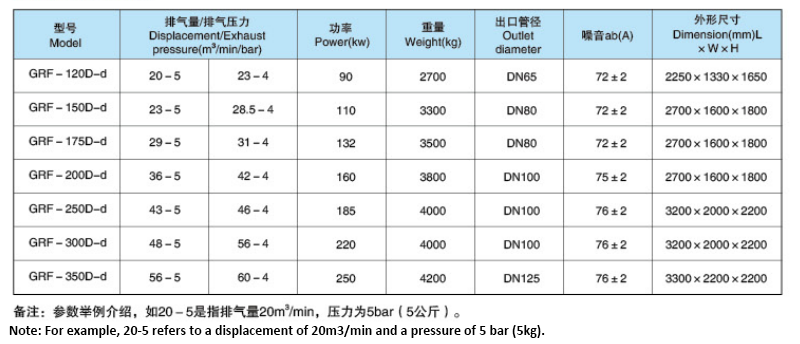

Main parameter