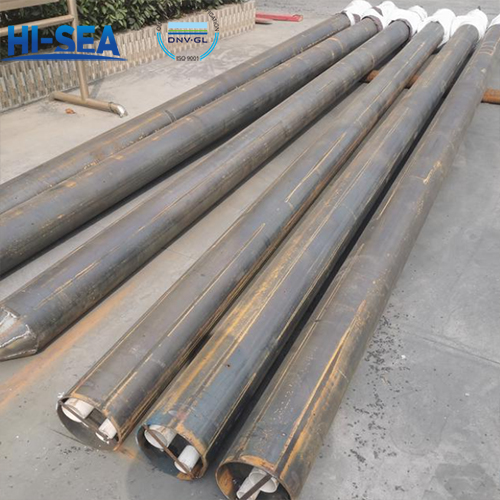

Sacrificial Anode for Deep Well

A deep well anode is typically an anode that is buried below 15 metres and placed in a vertical orientation. The main working environment is usually in the construction place where the space is narrow or the soil resistivity is very high. They are mainly divided into two types of anodes: open-ended anodes and closed-ended anodes.

Overview

Main Types

Open anodes refer to deep well anodes that are not backfilled. Open-ended deep well anodes are preferred when the water table is high and the anodes can be submerged year-round. The open anode is protected by a concrete casing to prevent the well wall from collapsing. Open anodes have the advantages of simple installation and easy maintenance. When mixed metal oxide linear anodes are used, installation is more convenient, especially in coastal areas and areas with high groundwater levels.

Closed anode means that the anode section is backfilled with coke filler to reduce the grounding resistance. The installation of closed anodes is more complicated, especially during the filling process, which has a great influence on the performance of the anode, and it is difficult to repair the problem once it occurs. In addition to design and material quality, the main factor affecting the quality of deep well anodes is the method of backfilling the filler.

Advantages

A distance between the anode and the structure of the facility to be protected allows for a more even distribution of cathodic protection current; and it reduces corrosion interference with other buried metal facilities in the vicinity. The materials used for deep well anodes are generally ferrosilicon anodes or mixed metal oxide cartridge anodes, and metallurgical coke or calcined petroleum coke is used to backfill the anode trench after laying the anode.

Where and Why to Use a Deep Well Anode System?

Typical Applications:

Cathodic protection stations for long-distance pipelines.

Protection of large storage tank bottoms or foundations.

Grounding grids for power plants or substations.

Protection of underground structures in crowded urban areas or high-resistivity rock layers.

Key Selection Factors:

Soil resistivity, water table, available space, and design life.

Choice between MMO linear anodes and high-silicon cast iron anodes.

While installation is more complex, deep well systems fundamentally address current distribution and interference issues that shallow-buried anode groundbeds cannot resolve, making them a critical safeguard for the long-term, safe operation of large, high-value underground assets.

Picture of Deep Well Anode