Round Goose-neck Ventilator

Round Gooseneck Ventilator is a common ventilation device widely used in factories, warehouses, garages and other places. It can effectively improve air quality through its specific design, especially in environments with poor air quality, high levels of harmful substances and odors, such as factories and warehouses. The working principle of this ventilation duct is to effectively control the inflow and outflow of air through its body, air inlet, air outlet, and electric device, thereby regulating the air quality and environment in the place.

Overview

Features:

1. It can effectively reduce harmful substances and odors in the air.

2. It can improve the air quality in the venue and ensure the respiratory health of personnel.

3. It can reduce the temperature and humidity in the workplace and improve the working environment.

4. It can improve the comfort and production efficiency of the venue.

5.The gooseneck ventilator is used on the natural and mechanical ventilation device on the exposed deck of all sorts of ships comply with CB / T 296-1996.

6.Surface treatment: painting, hot dipped galvanized, passivation.

7.Option: wire mesh, sound-proof, wave-preventing.

8.Material:stainless steel/carbon steel.

Test:

The manufacturing requirements for marine gooseneck ventilation ducts include surface smoothness, rust removal treatment, application of anti rust primer, and tightness testing.

Firstly, the surface of all parts should be kept smooth and free of burrs and cracks. The weld surface should be cleaned, the accessory switch should be flexible, and the moving parts should be coated with lubricating grease. This helps reduce friction, extend service life, and ensure the normal operation of the ventilation duct.

Secondly, the various components of the gooseneck ventilation duct should undergo rust removal treatment, which can be cleaned by shot blasting, spraying, or manual methods. After cleaning, they should meet the requirements of Sa2 or St2 level in GB8923. This step is crucial for preventing corrosion and improving the durability of ventilation ducts.

After manufacturing, the ventilation duct should be coated with two coats of anti rust primer to protect it from corrosion in the marine environment. This measure is crucial to ensure that the ventilation duct remains in good condition during long-term use.

Finally, the tightness test is an important step in ensuring the performance of the ventilation duct. When the cover plate is closed, the edge of the air duct should be uniformly pressed with filler and have continuous contact imprinting, with an imprinting width b ≥ t/2. In addition, the installation site at the root and the tightness test required by the classification society regulations are also essential steps. These requirements ensure the sealing and safety of ventilation ducts in ship use.

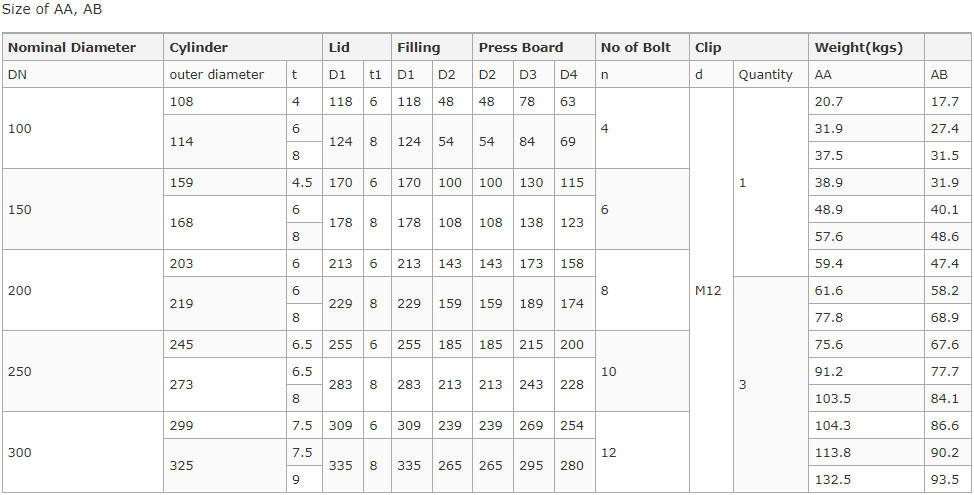

parameters: