Requirements and performance of marine oil lubrication stern shaft sealing apparatus

Marine oil lubrication stern shaft sealing apparatus is suitable for various types of ships with oil as the working medium. When producing marine oil lubrication stern shaft sealing apparatus, its requirements and performance should be comply with GB/T 25017-2010 standards.

Overview

Requirement:

Appearance:

The after sealing device is not allowed to be knocked, bumped, or scratched.

All parts of the assembly should be cleaned and cleaned thoroughly, without burrs, burrs, scales, rust, chips, oil stains, colorants, and dust.

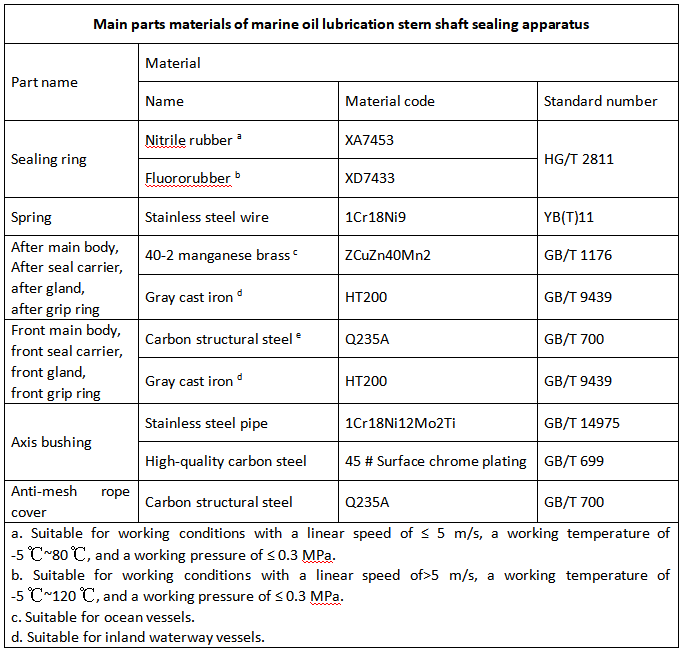

Materials:

The main components of the sealing device are shown in the table below, and other materials with performance not lower than the specified materials are allowed to be used as substitutes.

Design and Structure

The oil sealing device should be equipped with an oil chamber, and a circulator should be installed inside the oil chamber of the front sealing device.

The front sealing device is equipped with an external circulating oil tank, with a capacity of generally 10L or 15L. Its installation position is only higher than the upper shell of the sealing device, and it is equipped with a low oil level alarm.

The oil sealing device should be equipped with corresponding oil pipes, joints, ventilation and oil drain plugs.

When installing the oil sealing device, lubricating oil should be added to each oil chamber to prevent dry friction of the sealing ring.

The joint surface between the oil sealing device and the ship shaft tube and the hub should be equipped with sealing gaskets.

All fasteners and plugs of the oil sealing device should be embedded, and the top should not expose the outer end of the entity to prevent entanglement of the mesh rope.

After sealing device - It is generally recommended to install a structure with anti slip oil leakage pipelines (systems) according to the specifications and requirements of the shipowner.

Performance

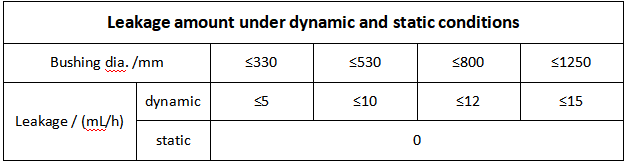

Sealing performance: The leakage amount of the oil sealing device in dynamic and static conditions should meet the requirements in the table below.

Wear resistance: The lip wear of the sealing ring after 100 hours of operation should not exceed 0.02 mm.

Pressure resistance of the casing: The casing of the oil sealing device should not leak for 0.5 hours under a pressure of 0.3 MPa.

Reliability: The average time between failures (MTBF) of the oil sealing device should not be less than 6400 hours.

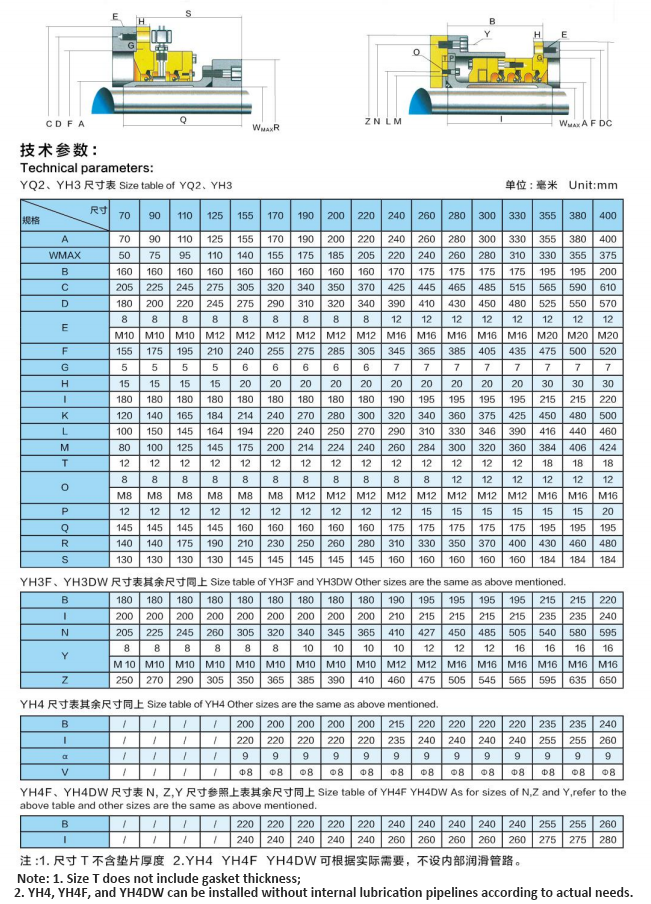

Main parameter

For more stern shaft sealing apparatus, please click here.

For more marine shaft system components, kindly please click here.