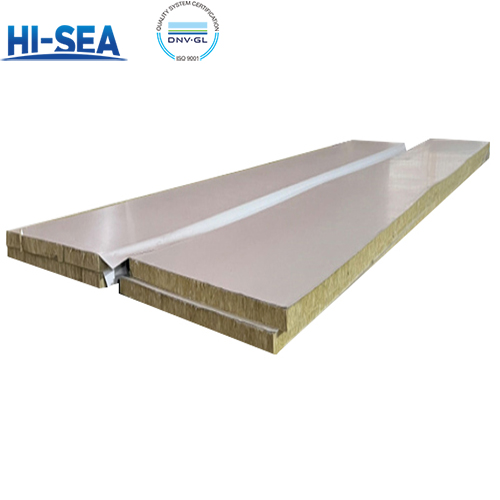

PVC Rock Wool Panel

PVC rock wool panels are widely used in construction and industrial applications due to their excellent thermal and acoustic insulation properties, fire resistance, and durability. These panels consist of a core made of rock wool, a type of mineral wool insulation, sandwiched between two layers of PVC (polyvinyl chloride) sheets.

Overview

Main Fire Protection Characteristics

It has the highest fire protection grade A1, which can effectively prevent the spread of fire.

Very stable in size, will not elongate, shrink or deform in fire.

High temperature resistant, melting point higher than 1000℃.

No smoke or burning droplets/fragments in fire.

No release of environmentally hazardous substances or gases in a fire.

PVC Rock Wool Panels for Marine Applications

1. Walls and Ceilings

Used to insulate walls and ceilings inside ships to help maintain a stable temperature inside the ship.

Effectively reduces heat transfer, improves the energy efficiency of the ship, and reduces the energy consumption of air-conditioning and heating systems.

2. Fireproof Isolation

Used for fireproof partitioning inside the ship to provide a fireproof barrier and enhance the safety of the ship.

Installed in each fire partition, engine room, galley and other high-risk areas of the ship to prevent the spread of fire.

3. Sound Insulation Treatment

Soundproof Walls and Ceilings

Installed near passenger cabins, recreation areas and engine rooms to reduce noise transmission and improve comfort for passengers and crew.

Suitable for areas requiring a quiet environment, such as staterooms, meeting rooms and recreation areas.

Picture of PVC Rock Wool Panel