Principle and Operation of Marine Hydrophore System

The marine hydrophore system is a device on a ship used to store a certain amount of water (seawater or fresh water), and by adjusting the air pressure (air compressor) to keep the water in the tank at a certain pressure.

The marine hydrophore system plays an important role in ships. It can provide reliable pressurized water sources for various water-using equipment and systems on ships, such as the sanitary water system, cooling system, and fire protection system, to ensure the normal operation of these systems.

Overview

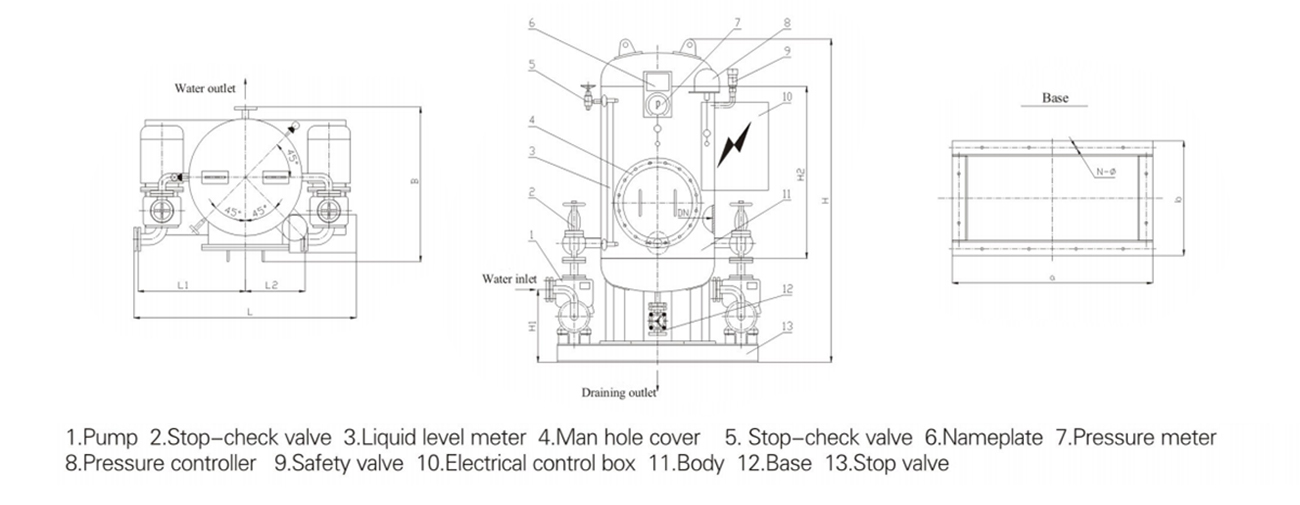

Structure Drawing

Principles

The working principle of the marine hydrophore system is to utilize the interaction between compressed air and water to maintain the stability of water pressure so as to ensure the safety of water used on the ship.

Clean water or slightly contaminated water from the water tank or water tank enters the suction port of the pump through the stop check valve, and is pumped by the pump into the diaphragm pressure tank with a built-in air bag for pressure storage and to supply water to the water-using system. The pressure in the pressure tank is controlled by the pressure switch. When the pressure in the air pipe is lower than the pump starting pressure set by the pressure switch, the water pump is started for pressure charging; when the pressure reaches the pump stopping pressure set by the pressure switch, the water pump stops. If the pressure in the pressure tank reaches the set tripping pressure of the safety valve, the safety valve will trip to ensure safety.

working process

Open the release valve at the bottom of the tank, release the water in the tank, then close the release valve.

Open the inlet water valve and close the output water valve.

Start the motor and inject water into the tank by water pump.

When the water level can be seen through the glass water gauge, close the inlet water valve and ctop the water pump.

Open the air inlet valve, start the air compressor to inject air into the fuel tank. When the pressure indicated by the pressure gauge reaches the lower limit pressure (such as 0.25 MPa), stop the air compressor and close the air valve.

Reopen the inlet valve and restart the pump. When the pressure gauge indicates the upper limit pressure (such as 0.4Mpa), the pressure relay cuts off the power and the pump stops working. The water level must be 3/4~ 4/5at glass water level gauge.

At this time, open the water outlet stop check valve, and the pressurized water can be put into use.

Conclusion

The above is the entire content of this article. In the article, we have detailedly introduced to you the working process and principles of marine hydrophore system. We hope that through this article, it can help you choose the marine hydrophore system.

Finally, if you have the need for procurement, you are welcome to visit our marine hydrophore system homepage or contact us at any time! Thank you again for your browsing!