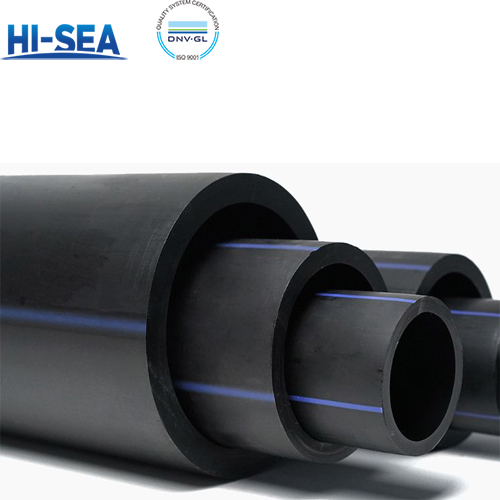

Polyethylene Pipe

Installation Methods

Butt Fusion: A process where the ends of PE pipes are heated and fused together to form a joint.

Electrofusion: Uses a special fitting with an electric coil that melts the pipe ends to create a joint.

Socket Fusion: Similar to butt fusion but uses a socket and spigot configuration for joining.

Overview

Advantages

Corrosion Resistance: PE pipes are highly resistant to chemical attack, making them ideal for transporting a wide range of fluids.

Flexibility: PE pipes can bend easily, which is beneficial in applications that require pipes to navigate around obstacles.

Longevity: They have a long lifespan, often exceeding 50 years in many applications.

Lightweight: Easier to handle and install compared to metal pipes.

Applications

Water Supply Systems: Used for drinking water, irrigation, and wastewater management.

Gas Distribution: Commonly used for natural gas and propane distribution.

Sewage and Drainage: Used in underground sewage systems due to their resistance to abrasion and chemicals.

Industrial Pipelines: Utilized for transporting chemicals and other industrial fluids.