Pneumatic Axial Flow Fan

Medium temperature: -25℃ ~ +50℃

Max relative humidity: 95%

Periodical swing: ±22.5°

Continued transversal incline: ±15°

Continued longitudinal incline: ±10°

Vibration: existent

Impact: existent

Overview

Working principle:

The noise reduction mechanism of marine pneumatic axial flow fans are mainly realized by optimizing blade design and internal flow field structure. The research shows that the blade perforation design can effectively reduce the noise, and reduce the flow separation and backflow by improving the flow characteristics inside the flow field, thus suppressing the noise.

Features:

Good anticorrosion performance: it can transport sea air containing salt fog and corrosive air such as oily fog and acid vapor.

Strong anti-sway, vibration and impact performance: adapt to various dynamic conditions that ships may encounter during navigation.

The casing can be made into an open type, which is convenient for maintenance and overhaul.

Reversible: adjust the wind direction as needed.

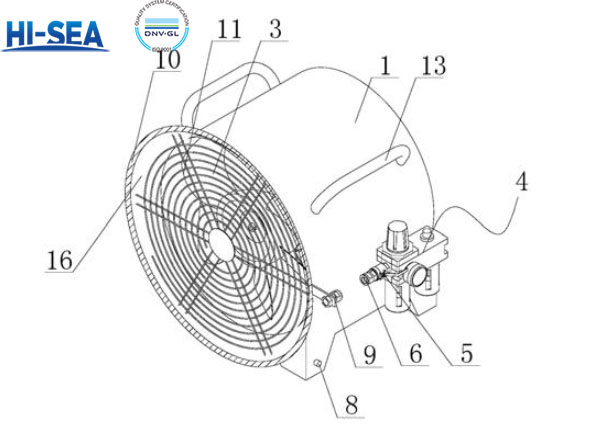

Drawing:

Picture: