Performance of Marine Air Compressors

The performance of marine air compressors refers to their performance and functionality in practical applications, including their efficiency, reliability, operability, safety, and adaptability.

Overview

1. The measured volumetric flow rate of the air compressor under rated conditions should be converted into a standard volumetric flow rate that is not less than 95% of the rated displacement, and the shaft power should not exceed the specified value of ISO or GB2028-91 standards.

2. The intermediate maintenance period (durability test time) of the air compressor is 1000 hours. The main components of the air compressor (cylinder block, cylinder head, cylinder sleeve, crankcase, piston, piston pin, connecting rod, connecting rod bolt, crankshaft, etc.) should not be damaged or damaged during the intermediate maintenance period, which affects the normal operation of the compressor. The main clearance values should not exceed the allowable limit values.

The service life of the air compressor valve plate and valve spring shall not be less than 1000h.

3. The structure of the air compressor should be able to ensure safe operation for 1 hour under the condition that the final exhaust pressure is 105% of the rated exhaust pressure at the rated speed.

When the first stage intake temperature is 50 ℃, the cooling water temperature is 30 ℃ (seawater or 40 ℃ (fresh water), and the final exhaust pressure is the rated exhaust pressure, the exhaust temperature of each stage (including air-cooled air compressors) shall not exceed 200 ℃.

5. Air temperature entering the air bottle:

The water-cooled air compressor shall not exceed the inlet water temperature plus 30 ℃.

The air-cooled air compressor shall not exceed the ambient temperature plus 40 ℃.

There should be a small fusible plug or alarm device at the outlet of the aftercooler of the air compressor. When the air temperature exceeds 121 ℃, an alarm should be issued (except for initial start-up or emergency air compressors).

6. When the air compressor operates under rated conditions, when the first stage intake temperature is 50 ℃, the lubricating oil temperature in the crankcase should not exceed 70 ℃. The flash point of lubricating compressor oil should be at least 20 ℃ higher than the maximum compression temperature inside the cylinder.

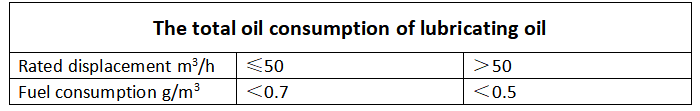

The total oil consumption of lubricating oil in the transmission mechanism and cylinder section of the air compressor should comply with the provisions in the table below.

When using pressure lubrication for the air compressor, the oil filter should be able to remove mechanical impurities, and the oil pump pressure should not be less than 0.1MPa and can be adjusted appropriately. Necessary measures should also be taken to ensure normal lubrication of the air compressor during start-up.

9. The cooling water pressure of the water-cooled air compressor should not be less than 0.05MPa.

10. The automatic control device of the air compressor unit is divided into two forms: semi-automatic and fully automated. Semi automated methods include automatic startup, automatic shutdown, automatic unloading, and automatic discharge.

11. The fully automated mode includes automatic startup, automatic shutdown, automatic unloading, automatic discharge, and additional necessary automatic protection devices and alarm devices.

12. If the user is damaged or unable to work normally due to poor product manufacturing quality within 12 months after delivery, and complies with the usage rules, the manufacturer shall repair or replace the parts for the user free of charge.

For more marine air compressor information, please click here.