Parsing the Key Performance Indicators of Marine Portholes

A porthole, sometimes called a side scuttle, is a round window, usually made of steel, aluminum, or copper alloy material, to meet the demanding environmental requirements at sea. Functionally, when the porthole is open, its role is to let light and fresh air into the dark cabin below the freeboard deck. It also provides a limited view of the outside world for occupants below deck. When closed, portholes provide a powerful watertight, airtight and sometimes light-tight barrier. This article will further discuss the requirements of porthole performance, hoping to answer your questions about procurement.

Overview

The Structure of Portholes:

A porthole can be composed of one, two or three main structural components, and its simplest form is similar in design and purpose to any other type of window.

The most main structure of a porthole is a circular glass disc wrapped in a metal frame and firmly fixed to the side of the hull by bolts or welding.

For a slightly more complex porthole, its glass disc is wrapped in a separate frame which is hinged to the base frame so that it can be opened and closed.

In addition, the most complex porthole is equipped with a metal storm cover on the basis of the previous structure. In maritime terms, the storm cover is called a deadlight. It can be securely fixed on the window when necessary. The main purpose of the storm cover, as the name suggests, is to protect the window from cracking under the influence of huge waves, or to prevent its debris and waves from entering the cabin after the glass breaks. Of course, if necessary, it is also used to block the light from entering the cabin.

Material mechanical properties of portholes:

According to GB/T 14413-2008 standard, light, medium and heavy duty Marine portholes should have the following requirements for their main parts:

| Type | Minimum Tensile Strength N/mm² | Minimum Elongation % |

| A (Heavy) | 300 | 15 |

| B (Medium) | 180 | 10 |

| C (Light) | 140 | 3 |

The Tightness Requirement of the Porthole:

Use a nozzle with a diameter of not less than 12mm and water flow with a pressure of not less than 0.2 MPa to impact the sealing part of the porthole at a distance of 1m to 1.5m, and there should be no water leakage inside the impacted part.

Install the porthole on the special hydraulic test chamber, and conduct the water pressure test in the following table way for 1 minute. It is required that there is no water seepage in all parts.

| Type | Test pressure kPa | |

| Put on the glass and open the storm cover | Leave the glass on and close the storm cover | |

| A (Heavy) | 150 | 100 |

| B (Medium) | 75 | 50 |

| C (Light) | 35 | --- |

Mechanical Strength Requirements of Porthole Storm Covers:

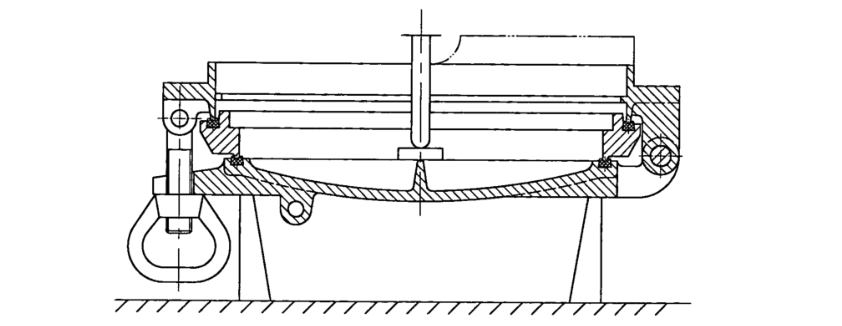

The porthole is not installed with glass, and the storm cover is tightly closed. With the mechanism shown in the following figure, simulate the possible direct contact impact with seawater. It is required that the heavy and medium porthole storm covers are under the pressure of 240 and 120 KPa respectively, and the permanent deformation does not exceed 1% of the nominal size of the porthole.

Conclusion:

That's all for the whole content. This article has introduced to you the basic structure of the porthole and the requirements for the relevant strength and performance of the porthole. I hope it can be helpful to you.