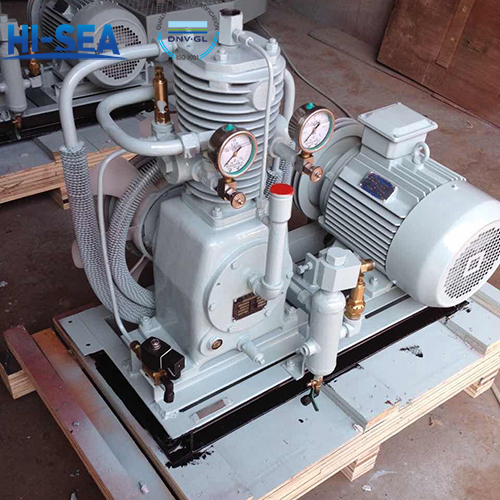

Operation and running management of marine piston air compressors

Marine piston air compressor is a common marine equipment used to provide high-pressure air to meet the needs of various equipment and systems on board. Its operation and operation management include: preparation before starting, starting, checking cooling conditions, checking lubrication, checking exhaust pressure and temperature, timed water discharge, etc

Overview

1. Start

(1) Preparation before startup. For air compressors that have just been repaired or have not been used for a long time, they should be turned 1-2 times to check if they are normal; Check if the oil level in the crankcase remains within the specified scale on the dipstick. When using splash lubrication, it is advisable to immerse the crankshaft bottom dead center oil spoon into the oil by 20-30mm, and the oil spoon should be 2-3mm away from the bottom. For low-pressure cylinders lubricated with drip oil, the oil level in the oil cup should not be less than 1/3 and the drip amount should be maintained at 4-6 drops per minute; Open the inlet and outlet valves of the cooling water and introduce the cooling water; Open all valves from the air compressor to the air cylinder; Check if manual uninstallation is placed in the uninstallation position; Check if the discharge valves of the air compressor are in the open position.

(2) Start. After the preparation work is ready, jog 1-2 times first; If there are no abnormalities, switch to normal operation. During the startup process, pay attention to observing the changes in current and whether there are any abnormal sounds; After the current is normal, observe whether the automatic unloading air compressor has been automatically uploaded, and manually stop unloading the manual unloading air vcompressor; And close all levels of relief valves from low to high; Check for any air or water leaks; Check if the exhaust temperature, pressure, and cylinder head temperature are normal.

2. Key inspection points during operation

(1) Check the cooling condition. Pay attention to checking the inlet and outlet temperatures of the cooling water. Generally, the temperature rise at the inlet and outlet should be between 10-15 ℃. The inlet pressure of cooling water should be maintained at 0.07~0.3MPa, with a flow rate of about 1~2m/s. If it is found that the compressor has run out of water during operation, it must be stopped immediately and checked for damage after natural cooling. It is important to avoid immediately passing cooling water to the cylinder when it is very hot, which may cause the cylinder to explode.

(2) Check the lubrication condition. When the suction temperature does not exceed 45 ℃, the lubricating oil temperature of water-cooled air compressors should not exceed 70 ℃, and air-cooled compressors should not exceed 80 ℃. For pressure lubrication, the lubricating oil pressure should not be less than 0.1MPa. At the same time, it is necessary to regularly check the oil level in the crankcase and other components.

(3) Check the exhaust pressure and temperature. Pay attention to observing the changes in exhaust pressure at all levels of the air compressor, and check if it increases synchronously with the increase of air cylinder pressure. The exhaust temperature should not exceed 160 ℃, and the air temperature in the air cylinder should not exceed the inlet temperature plus 30 ℃ when water-cooled, and the ambient temperature plus 40 ℃ when air-cooled.

(4) Timely drainage. Drain the air compressor at work every 2 hours. When discharging water, it is necessary to observe whether there is too much lubricating oil in the discharged water.

3. Parking

For non automatic control air compressors, manual unloading should be carried out first, and then all levels of relief valves should be opened from high to low to prevent accidents during disassembly and inspection due to air in the cylinder.

At present, more advanced ships use automatic control for their air compressors. It can achieve automatic start stop, automatic unloading, automatic discharge, and automatic control of cooling water of the air compressor. Usually, there are two air compressors working in parallel, and the starting and stopping pressure values of these two air compressors are different. Generally, the starting pressure of the priority working air compressor is 2.5MPa, and the stopping pressure is 3.0MPa; The standby air compressor has a starting pressure of 2.4MPa and a stopping pressure of 2.9MPa.

For more marine air compressor information, please click here.