Oily Water Separator

The YSZ series 15ppm bilge water separator is meticulously designed and crafted in accordance with the IMO resolution MEPC.107(49), namely the Guidelines and Specifications for Pollution Prevention Equipment for Machinery Space Bilges of Ships. This remarkable equipment is dedicated to treating the bilge water of various ships. Once processed by this equipment, the bilge water can meet the standard stipulated by the IMO MEPC.107(49) Resolution and be safely discharged overboard.

Boasting a compact structure, diminutive size, and lightweight design, this equipment not only offers a large treatment capacity but also exhibits high reliability. Moreover, it is easy to operate and maintain. The bilge water treated by this equipment fully complies with the requirements of the IMO resolution MEPC.107(49) Resolution, Guidelines and Specifications for Pollution Prevention Equipment for Machinery Space Bilges of Ships.

The YSZ series 15ppm bilge water separator is equipped with automatic/manual heating, automatic oil discharge, automatic alarm, and automatic recording of the operating procedure. Manual oil discharge can be employed when necessary. This equipment is particularly suitable for use on ships with a high degree of automation.

Overview

Working Principle

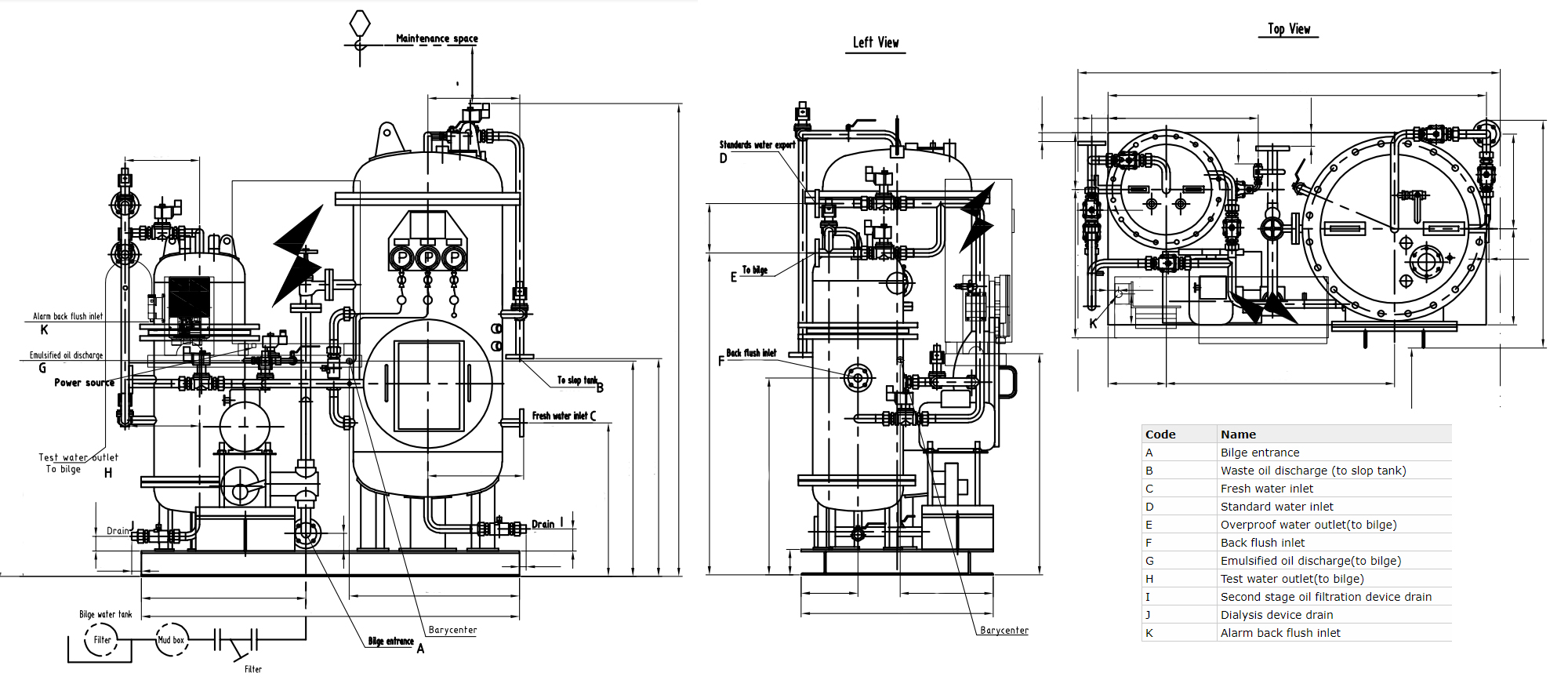

The separator adopts three-stage oil filtering method. Bilge water is pumped by the bilge water pump into the first-stage oil-filtering room, where the first-stage separation is performed using the specific gravity difference of oil and water and the floating oil is separated from the water through the method of gravity. After the first-stage separation, the bilge water still contains small oil particles of diameter ≥0.5μ(i.e. emulsified oil), which are coalesced together (thus become bigger) through the coalescer in the second-stage oil-filtering room, and then be separated and float to the surface. Bilge water satisfying the discharge standard through the second-stage treatment will be directly discharged overboard. If the bilge water contains too much emulsified oil, it still fails to meet the discharge standard after the second-stage treatment, then the third-stage dialysis apparatus will be put into operation automatically to enable the bilge water to meet the discharge standard. The separated dirty oil is collected in the top of oil-filtering room. When the collected dirty oil reaches certain amount, it will be automatically discharged to the dirty oil tank (for details see the system schematic diagram of the 15ppm bilge water separator).

Main Product Parameter Sheet

| Mod. | YSZ- | ||||||||||

| YSZ-0.1 | YSZ-0.25 | YSZ-0.5 | YSZ-1.0 | YSZ-2.0 | YSZ-3.0 | YSZ-4.0 | YSZ-5.0 | ||||

| Treatment capacity m3/h | 0.1 | 0.25 | 0.5 | 1 | 2 | 3 | 4 | 5 | |||

| Discharge standard | ≤15ppm, satisfying(IMO)MEPC.107(49) | ||||||||||

| Working pressure | ≤0.3MPa | ||||||||||

| Motor power (kw) | 0.12 | 0.18 | 0.25 | 0.37 | 0.75 | 1.1 | 1.5 | 1.5 | |||

| Electric heating power(kw) | 1 | 2 | 2~3 | 3 | |||||||

| Power supply | 3Ph/380V/50Hz; or 3Ph/440V/60Hz; | ||||||||||

Specifications

spare parts list

No. | Name | Qty. |

1 | Body | 1set |

2 | Electric control box | 1set |

3 | Solenoid valve | 4set |

4 | Solenoid valve | 5set |

5 | Piston pump | 1set |

6 | Marine motors | 1set |

7 | Alarm | 1set |

8 | Copper cock | 1pcs |

9 | Stop check valve | 1pcs |

10 | Pipe fittings | 1set |

Maintenance

Daily maintenance

1. The suction filter assembly must be washed at least once for each week. If the strainer mesh is damaged, it should be timely repaired or replaced with 80 stainless steel wire mesh.

2. Inspect the operating state of the bilge water pump, such as the operating temperature, noise, leakage and the belt tension etc.

3. Regularly inspect and record the working pressure of the manometers. Whether the equipment is operating normally or not may be decided by the pressure differences of the coalescer and dialysis apparatus.

4. Inspect the operating state of the automatic oil-discharging device.

5. Inspect he operating state of the 15ppm bilge water alarm device according to the Operating Instructions for the 15ppm Bilge Water Alarm Device.