MPUV Ballast Water Management System

Our medium-pressure ultraviolet ballast water management system utilizes a 40-micron self-cleaning filter combined with medium-pressure ultraviolet (MPUV) disinfection technology. It has a simple structure, superior performance, and the design allowance can meet stricter emission standards. Therefore, it can provide customers with a wide range (50 to 4,000 cubic meters/hour) of ballast water management solutions. In addition, we can also provide customers with other technical types of ballast water management systems, including but not limited to electrolysis, nitrogen-charging and deoxygenating and other technical types. For more details, welcome to contact us directly!

Overview

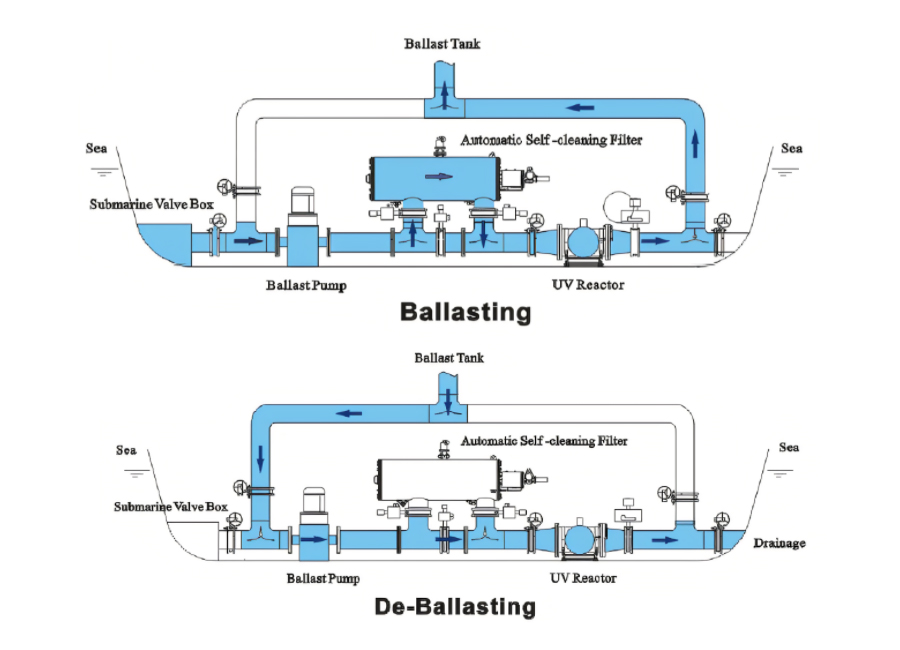

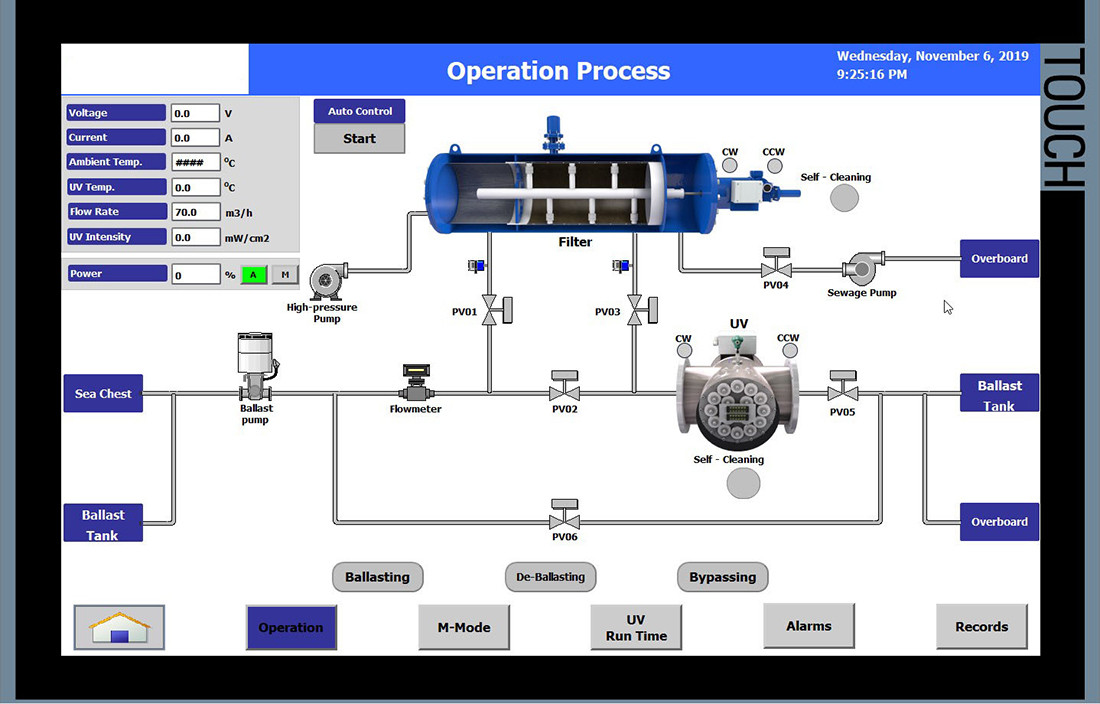

System Principles

Ballasting

During the ballasting process for vessels, ballast water enters into the BWMS via the ballast pump, passes through the self-cleaning filter and MPUV reactor successively for treatment, and finally flows into the ballast tank. Large-size inorganic particles, most of the zooplankton and phytoplankton (such as alga) can be removed in the filter, to ensure the effectiveness of downstream MPUV disinfection. Thereafter, 200-280 nm wav elength UV irradiation of the MPUV reactor achiev es disinfection and inactivation of the residual plankton, bacteria and viruses in the ballast water by damaging the genetic materials.

De-Ballasting

During the de-ballasting process, ballast water from various ballast tanks flows into the BWMS via the bllast pump by way of the valve and pipe system, directly enters the MPUV reactor, and then is discharged overboard. During the process, water does not enter the filter, so as to prevent the inactiv ated microorganisms from photoreactivation repair or secondary reproduction in the ballast tanks.

Features

◆Simple & Flexible

The system has a simple structure, and is easy to use. install, operate and maintain. According to the space requirements, different delivery ways can be adopted.

◆Stable & Reliable Performance

The system has stable and reliable performance, because of its advanced backflush filtration technology, core parts made of high-grade materials and critical components of the first-tier brands.

◆Design Allowance to Meet More Stringent Discharge Requirements

The system has sufficient UV design allowance and can meet higher regional discharge standards when operating in high-power mode.

Power-saving mode allows the system to automatically adjust the ultraviolet radiation intensity according to the incoming water quality.

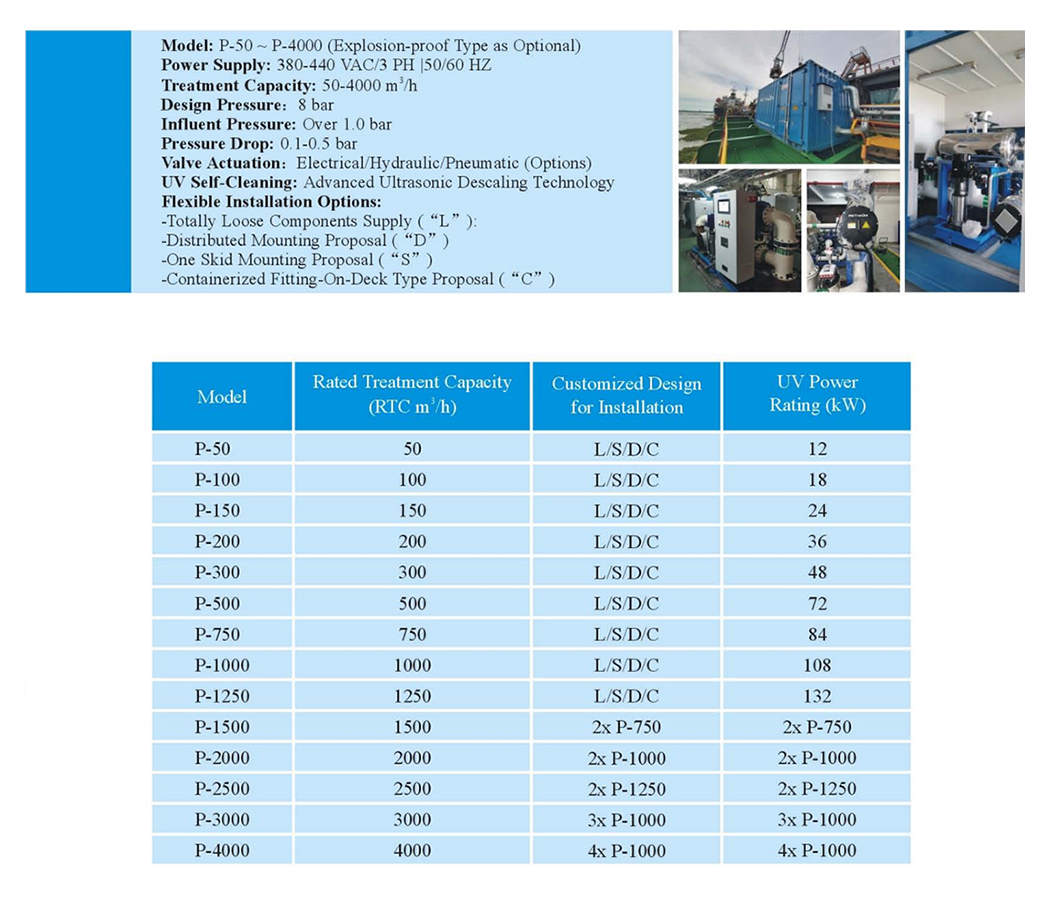

System Models & Specifications

Main Structures

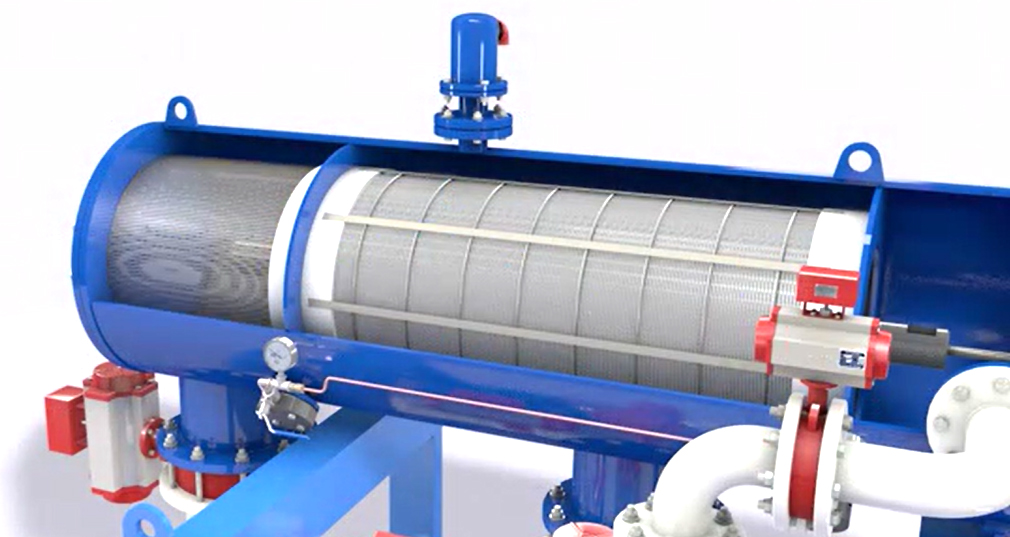

Self-Cleaning Filter

The operational stability and the treatment capacity of the BWMS largely depend on the performance of the filter. The system is equipped with a 40 pum high-precision self-cleaning filter. On one hand, the design ensures excellent filtering performance of the filter and minimizes the entry of plankton and sediment into the ballast tank. On the other hand, high-precision filtration ensures the efficient use of subsequent UV sterilization, greatly improving the treatment performance of the entire system ultimately. The filter housing and the mesh screen are made of duplex stainless steel 2205 and 2507, respectively, with a service life of over ten years under normal maintenance and servicing conditions. The unique mesh screen structure and sewage mechanism design greatly enhance the self-cleaning function of the filter under the backflush action of the high-pressure backflush pump, thereby enabling the entire system to cope with the challenges of poor water quality.

◆High-grade material, long service life.

◆Unique Filter structure ensuring high removal rate.

Specifically, 96% zooplankton (> 50% um) removal; 50% phytoplankton (10-50 um) removal; 98% total suspended solids (TSS, 2,500 ppm influent) removal.

◆Filter unit continues filtration even during the automatic backflush operation. The filter is not liable to blockage, thanks to the high pressure of the backflush pump.

◆Short ballasting/de-ballasting time.

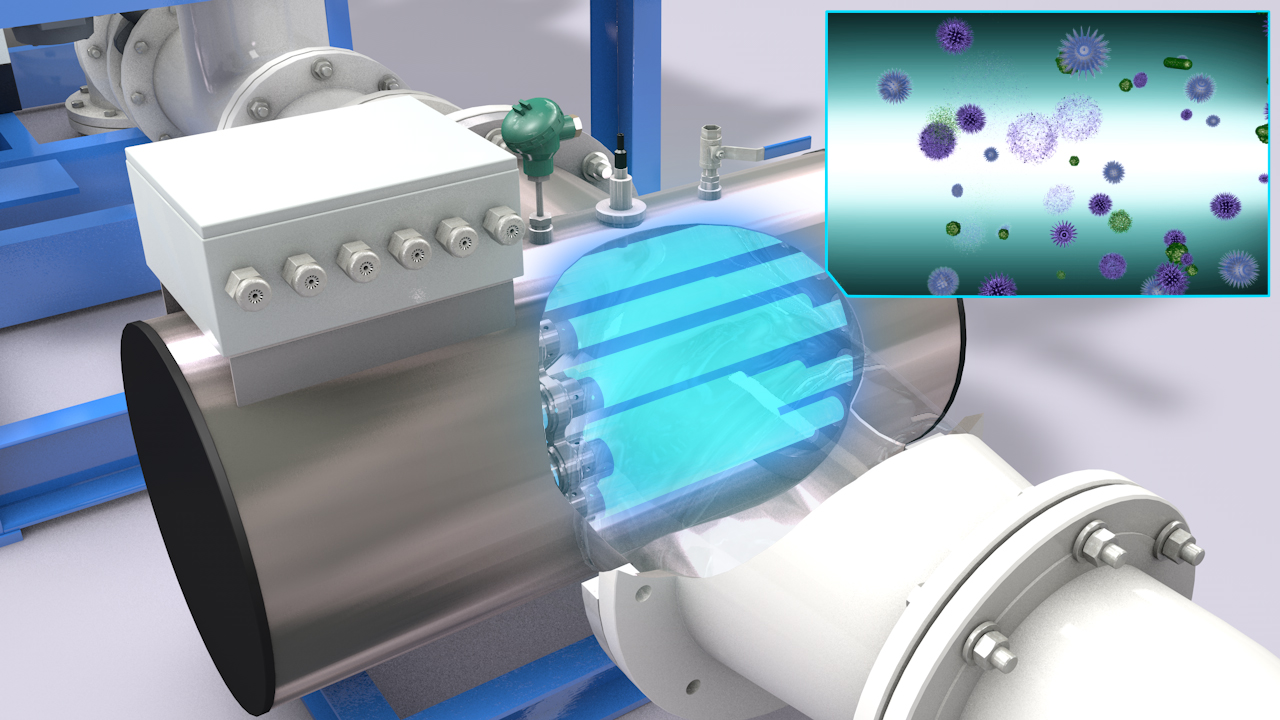

Medium Pressure Ultraviolet (MPUV) Reactor

Being a developed water disinfection technology, ultraviolet disinfection does not produce chemical substances or pose an occupational hazard to crews, and is safer and more economical and environmentally friendly than others. The UV design dosage reflects the biological inactivation ability of a UV reactor. There are many UV reactors with different UV dosage designs on the market. By adopting a UV reactor with a large UV dosage design redundancy, clients not only do not have to worry about sampling and inspection by the port state prosecutors, but also can avoid possible requests of subsequent system upgrades.

economical mode, the system automatically adjusts the UV output based on water volume and quality. In view of economical mode, the system automatically adjusts the UV output based on water volume and quality. In view of the design concept of high efficiency UV output, the system is more economical and power-saving when compared to ordinary UV reactors. Secondly, the UV dosage configuration of the system has redundancy, so that in high power performance mode, it can meet relatively stricter ballast water discharge standards. As a result, it can meet higher environmental requirements of certain sea areas without the need to upgrade or modify the system.

◆High environment adaptability, not affected by water quality parameters such as temperature, pH or salinity.

◆Equipped with a temperature monitor to set off an alarm and shut down the system in case of abnormal operation, so as to protect the system.

◆Equipped with a second generation ultrasonic self-cleaning mechanism, which effectively prevents the formation of biological and inorganic scales on the surface of the quartz lamp sleeve, and has a significant removal effect on the water scale.

◆Visual design of UV lamp working status in the Human-Machine Interface(HMI), allowing timely and accurate fault diagnosis and faciltating UV lamp replacement.

◆Chemical-free operation, safe for the crews and the vessels.

Contral Unit

Validated by stringent environmental and electro-magnetic compatibility (EMC) tests, the electrical panel is able to withstand various challenging ambient conditions, such as extreme temperatures, humidity, vibrations, inclination, and electromagnetic interference. The electronic components are of famous brands, stable and reliable, and purchasable worldwide for replacement. Its Human-Machine Interface (HMI) is designed with comprehensive functions, rich contents, clear logic, and beautiful and simple style, and is easy to understand and operate. The system can operate automatically or manually, automatically monitoring and recording all key operating data and parameters. In case of abnormal operation, the system will trigger an audible and visual alarm. In an emergency, the system will automatically stop operation.

◆Real-time monitoring of key parameters: voltage, current, temperature flow rate, UV intensity, filter differential pressure.

◆One button startup of all operation modes (Ballast, De-ballast and Bypass and Stripping), for automatic running.

◆Multilevel automatic control and protection design, that is, automatic system shutdown when the PLC program or sensors fail.

◆Filter self-cleaning by Auto/Manual control.

◆UV quartz sleeve self-cleaning by Auto/Manual control.

◆UV power consumption being automatically adjusted to match the treatment capacity.

◆UV lamps lifetime recording.

◆Alarm and emergency shutdown in case of various abnormal operations.

◆Key parameters settable for operation & maintenance.

◆Operating BWMS with different limits of access.

◆GPS signal accessing and processing for vessels.

◆Automatic recording and alarming for bypass operation.

◆External remote communication protocol and interface: Modbus RS 485, or Ethernet.

◆Remote operation and remote data transfer.

◆Critical data recording, storage time not less than 36 months (USB).

Conclusion

For additional details, please contact us! For other types of products, please feel free to contact us, or visit our Ballast Water Management System homepage to learn more!