Marine Wet Unit

The marine wet unit plays a crucial role on ships. It is an independently functional area carefully designed to meet the sanitary needs of crew members and passengers. This area ingeniously combines multiple functions such as toilets and bathrooms to form a comprehensive sanitary space. Here, people on board can enjoy the convenience brought by a series of basic sanitary facilities such as washing, toileting, and showering. The ship's sanitary unit can provide people on board with a relatively private, convenient and fully functional environment, meeting their various sanitary needs during the voyage and ensuring their quality of life and health status. This enables crew members and passengers to feel the same basic sanitary guarantee as on land during the long sea journey and provides indispensable support for the normal operation of ships and the comfortable life of personnel.

Overview

1. Definition and Basic Functions:

Definition: The marine wet unit is an independent functional area on ships specifically designed to meet the hygiene needs of crew members and passengers. It integrates functions such as bathrooms and showers, providing basic hygiene facilities such as washing, toileting, and showering for people on board.

Functions:

Washing function: Equipped with a washbasin and faucet, providing cold and hot water for daily hand washing, face washing, and simple personal cleaning.

Toileting function: Equipped with sanitary ware such as toilets or squat toilets, and equipped with a corresponding drainage and treatment system for excretion to ensure proper discharge and treatment of waste.

Showering function: Equipped with shower heads, showers, and other showering equipment to provide hot water showers, allowing people on board to keep their bodies clean during voyages.

2. Structure and Design Features:

Structural composition:

Wall panels and ceilings: Usually made of strong, moisture-proof, and corrosion-resistant materials such as stainless steel, aluminum alloy, glass fiber reinforced plastic (GRP), etc., which can effectively resist the erosion of harsh marine environments such as moisture and salt spray.

Bottom plate: The bottom plate needs to have good waterproof and anti-slip properties. Generally, special anti-slip floor tiles or rubber floors and other materials are used to ensure the safety of people during use.

Sanitary ware: Including toilets, squat toilets, washbasins, shower heads, etc. The selection and installation of these sanitary wares need to meet the special requirements of ships, such as resistance to shaking and impact.

Hardware accessories: Hardware accessories such as door hinges, door locks, faucets, and showers need to have high strength and corrosion resistance to ensure the reliability of long-term use.

Lighting system: Provide sufficient lighting for people to carry out various activities in the wet unit. Lighting fixtures usually have waterproof and explosion-proof functions.

Design features:

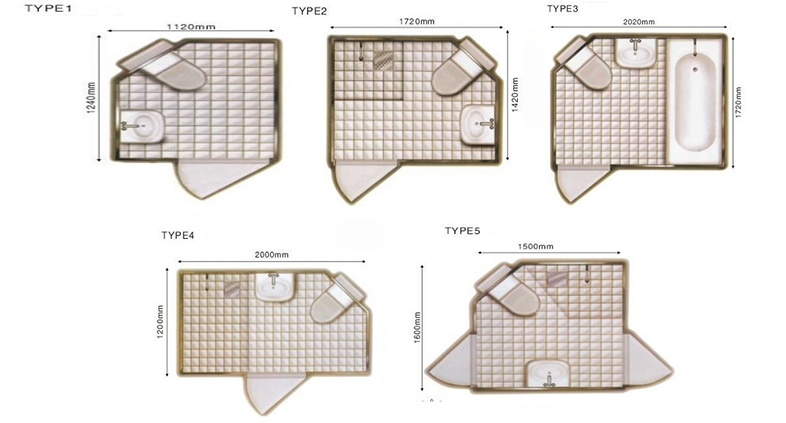

Efficient space utilization: Due to the limited space on ships, the design of marine wet units needs to fully consider the efficiency of space utilization, adopt a compact layout, and provide complete functions in a limited space as much as possible.

Sturdy and reliable structure: During sea voyages, ships will face various shakes and bumps. The structure of marine wet units must be strong enough to withstand these external forces and ensure safety during use.

Excellent waterproof and moisture-proof performance:

The marine environment is humid, and seawater is corrosive. Therefore, the waterproof, moisture-proof, and anti-corrosion performance of marine wet units is the focus of design. All materials and connection parts need special treatment to prevent water leakage and corrosion.

Good ventilation: To keep the air in the wet unit fresh, a good ventilation system is needed to discharge odors and moisture in time. Ventilation equipment usually has waterproof and explosion-proof characteristics.

3. Material Selection:

Metallic materials:

Stainless steel: It has high strength, corrosion resistance, and easy cleaning. It is often used in parts such as the frame, wall panels, and sanitary ware brackets of the wet unit, ensuring that it is not easy to rust and damage during long-term use.

Aluminum alloy: Lightweight and high-strength, with good processing performance, suitable for making components such as doors, windows, and frames of the wet unit, which can reduce the overall weight of the ship.

Non-metallic materials:

Glass fiber reinforced plastic (GRP): It has good corrosion resistance, insulation, and waterproof properties. It can be used to make large components such as wall panels and ceilings of the wet unit, which can effectively reduce the construction cost of ships.

Ceramics: Ceramic materials are often used to make sanitary wares such as washbasins and toilets. The surface is smooth, easy to clean, and has good corrosion resistance and wear resistance.

Rubber: Rubber materials have good elasticity and anti-slip properties. They are often used to make components such as floor mats and seals of the wet unit, which can play a role in anti-slip, shock absorption, and sealing.

4. Installation and Maintenance:

Installation requirements:

Installation location: The installation location of the marine wet unit needs to be selected according to the ship's design and usage needs. Generally, it is installed near the crew living area or passenger activity area for convenient use.

Fixing method: Due to the shaking and bumping of ships during voyages, the marine wet unit needs to be fixed firmly by methods such as welding and bolt connection to ensure that it does not shift or loosen during use.

Pipeline connection: The drainage pipes and water supply pipes of the wet unit need to be correctly connected to the ship's main pipeline system to ensure smooth water supply and drainage. At the same time, good sealing and anti-corrosion treatment of pipelines should be done.

Maintenance points:

Daily cleaning: Regularly clean the wet unit to keep the sanitary wares, floors, walls, and other parts clean to prevent the growth of dirt and bacteria.

Equipment inspection: Regularly check the usage of sanitary wares, faucets, showers, and other equipment, and timely find and solve problems such as leaks and blockages.

Anti-corrosion treatment: Regularly perform anti-corrosion treatment on metal parts, such as applying anti-corrosion paint and replacing corroded parts, to extend the service life of the equipment.

Ventilation system maintenance: Regularly check the operation of the ventilation system, clean ventilation ducts and filters to ensure good ventilation effect.

5. Relevant Standards and Specifications:

International standards: The marine wet unit needs to comply with relevant standards and specifications formulated by the International Maritime Organization (IMO), such as requirements for the provision of sanitary facilities, the design of drainage systems, and fire resistance.

Classification society standards: Different classification societies, such as the China Classification Society (CCS), Lloyd's Register (LR), American Bureau of Shipping (ABS), etc., will also formulate corresponding inspection standards for marine wet units based on international standards and their own experience, and conduct strict inspection and certification on the materials, structure, and installation of wet units.

6. Application Fields:

Merchant ships: Including various types of merchant ships such as cargo ships, passenger ships, and oil tankers. The marine wet unit is one of the necessary facilities on merchant ships, providing basic hygiene services for crew members and passengers.

Cruise ships: As a large-scale marine tourism ship, cruise ships have higher requirements for wet units. They not only need to provide comfortable and beautiful sanitary facilities but also need to have good ventilation, lighting, and other conditions to meet the high-quality needs of passengers.

Warships: The wet units on warships need to meet the special requirements of military operations, such as having high impact resistance and fire resistance, and at the same time being easy to maintain and manage.

Engineering ships: Such as marine engineering ships and dredgers. Crew members work on board for a long time, and the demand for wet units is also urgent. The marine wet unit provides necessary living guarantees for crew members.

For more detailed information, welcome to visit the homepage of our Marine Wet Unit System for understanding, or contact us by email directly.