Marine Water Driven Fans

Marine water driven fans are kind of axial flow fans. The power source comes from the inlet pressure water source to drive the turbine built into the fan, the turbine rotates to drive the gear mechanism and the impeller rotation. The inlet pressure water drives the turbine and is discharged from the outlet on the other side. Fan design of the water flow channel and air flow channel is isolated, so as to avoid the water flow into the air to form a static water mist and then mixed with the dangerous gases in the warehouse. The fan is bi-directional and can be used as an air supply fan or an exhaust fan

Overview

Key Part:

The core component of the marine water-driven fan is the rotor, which employs a special structure that drives the rotor to rotate through the impact of the water flow. Specifically, the water flow enters the rotor chamber through a conduit and shoots out from the relative notches of the rotor, creating a series of ultraviolet wind pulsations, which in turn compresses the air and delivers it to where it is needed. Since the water-powered blower utilizes the kinetic energy of the water flow to produce compressed air, it is characterized by low energy consumption and does not produce pollution. The disadvantage is that the cost of the water blower is high, need to occupy a large site, and in the operation process will produce a certain amount of noise and vibration.

Advantages:

When the drive medium (seawater) flows through the turbine, it provides cooling for the equipment. For certain applications, the discharged water mist can also mix with the airflow to scrub air and remove combustible gases.

If the fan outlet becomes unexpectedly blocked, the turbine speed will naturally decrease or stop, but it will not burn out due to overload like an electric motor. Once the blockage is cleared, operation resumes automatically.

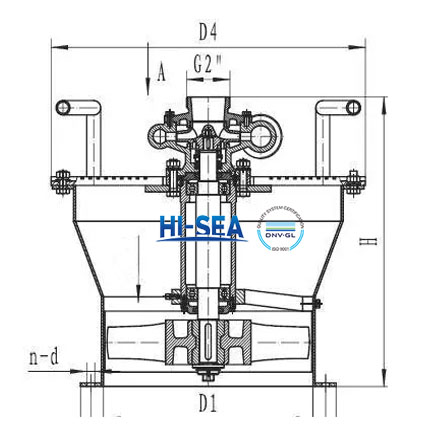

Drawing: