Marine Wastewater Treatment Plant

The Marine Wastewater Treatment Plant is used to handle the domestic sewage from the sewer of toilets on ships, and can also be used for the disinfection treatment of gray water to make it meet international discharge standards.

The operation of this device is fully automatic control, and it has an alarm facility that shows the sewage loading status in the cabinet. This device has a small volume and strong processing ability, and can be used by many people under the condition of low flushing water.

This device is convenient for installation and can be directly welded or fixed on the ship's mounting base with bolts.

In short, if you have relevant needs, we will provide you with a solution for domestic sewage treatment on ships (not limited to the content of this article). Welcome to contact us via email <hs10@cqhisea.com>!

Overview

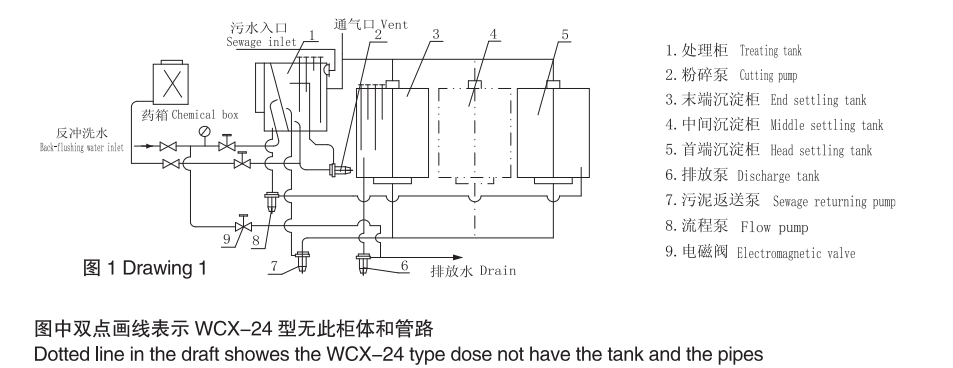

System Principle

This device adopts physical/chemical methods to handle the domestic sewage from the sewer of toilets on ships.

The sewage is first input into the treatment cabinet. When the sewage in the cabinet reaches the middle position, the device starts to work procedurally, and its working time is about 18 minutes, which is preferentially controlled by the time relay. The domestic sewage containing solid residues is repeatedly circulated and crushed in the treatment cabinet by the crushing pump until the solid residues are small enough to pass through the filter (stagnation/reduction) net. At the same time, there is flushing water constantly flushing the filter to prevent the solid residues from accumulating on the filter and causing blockage. During the crushing cycle, a certain amount of sodium hypochlorite is added for disinfection treatment, and the addition of disinfectant is controlled by the stop valve.

The domestic sewage that has been crushed, filtered and disinfected is pumped into a series of connected sedimentation cabinets by the process pump. The flow rate in the sedimentation cabinets slows down, and its suspended solids sink. The settled sludge is returned to the treatment cabinet by the sludge return pump for re-circulating crushing.

The treated process water is gradually clarified in a series of sedimentation cabinets. When the clarified liquid in the cabinet reaches the middle position, due to the trigger of the sensor, the discharge pump works and discharges it outboard. When the liquid level in the cabinet reaches the low position, the discharge pump automatically stops.

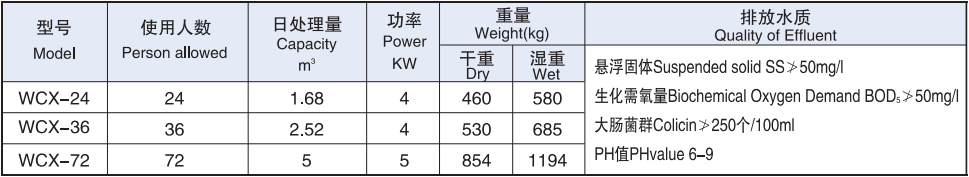

Main Technical Parameters

System Principle Drawing

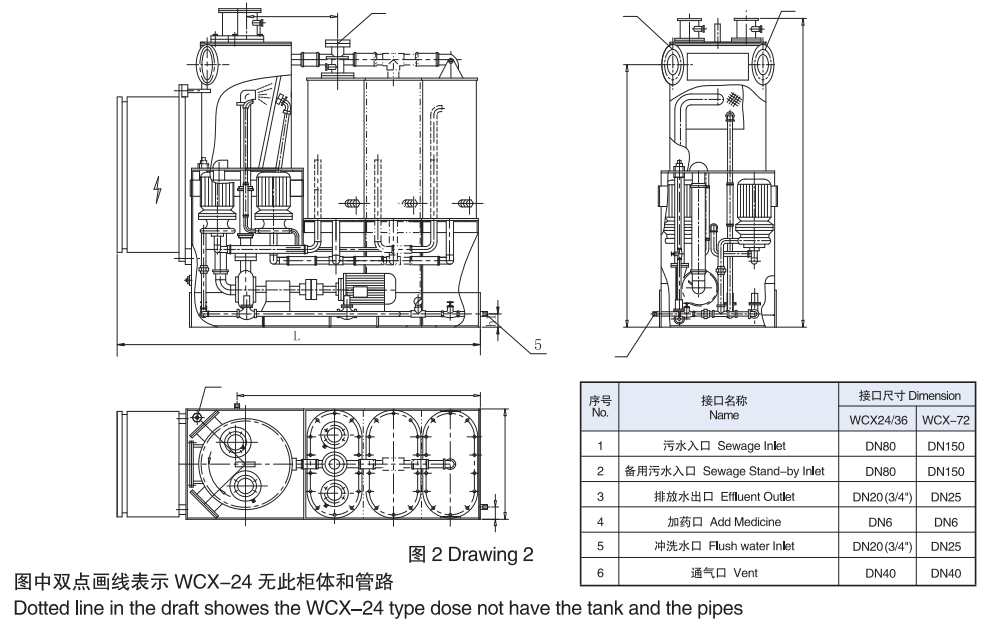

Structure Drawing

Conclusion

For additional details, please contact us! For other types of products, please feel free to contact us, or visit our Marine Sewage Treatment System homepage to learn more!