Marine Stainless Steel Capstan

A marine stainless steel capstan equips the ships and vessels with strong and indispensable advantages for marine tasks. It can be powered by electric or hydraulic type, and built into vertical or horizontal. It is designed with durable low maintenance components and built in accordance with recognized marine and offshore standards. Its robust units can work in the most caustic offshore conditions for years. We are able to achieve this by limiting the number of parts, making key parts robust, using stainless steel and opting for high-quality rotating parts.

Overview

The marine stainless steel capstan provides innovative solutions and equips professionals in the marine industries. In addition to the corrosion-resistance, the stainless steel has high strength and good toughness and can withstand high pressure and high temperature, free from deformation and fracture. Its smooth and complete surface is not only beautiful but also easy to maintain and clean. The stainless steel can also be processed in various ways so that the capstan can be easily customized into different shapes and sizes.

Features:

Driven by electric or hydraulic

Can be equipped with gypsy

Local or remote control

Hydraulically or manually operated clutch and brake

High tenacity, strong construction

Approved by CCS, BV, RS, RINA.

Can be customized according to your needs.

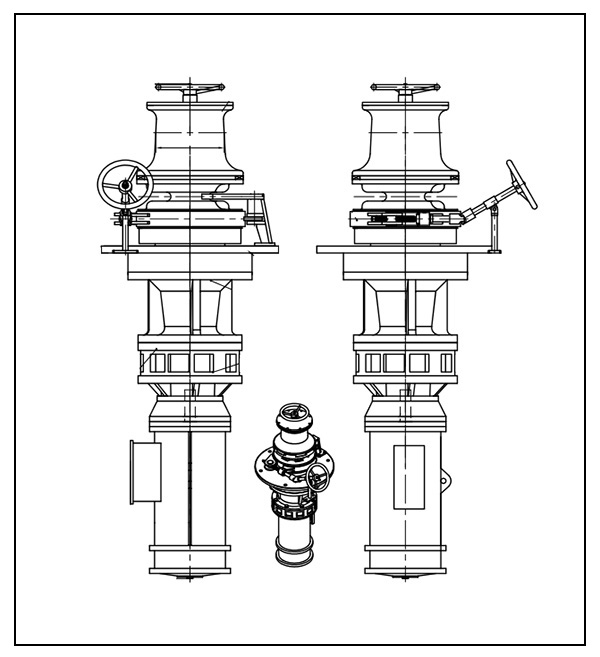

Drawing for Marine Stainless Steel Capstan

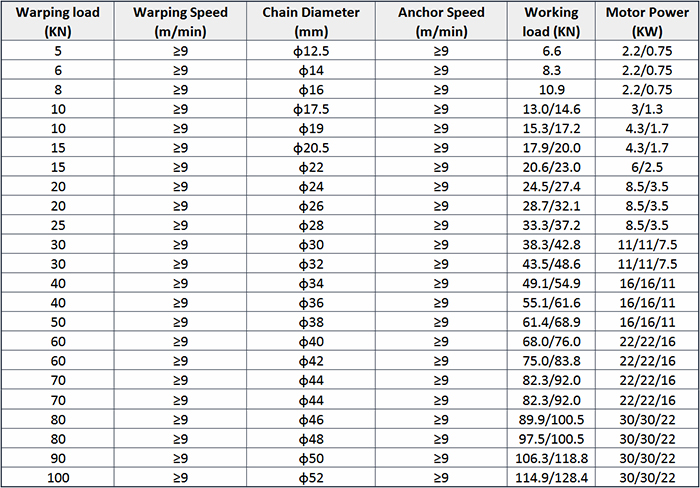

Main Technical Specifications