Marine Sewage Treatment System

The marine sewage treatment system is a key equipment under Annex IV of the International Convention for the Prevention of Pollution from Ships (MARPOL 73/78).

This system device can be used to treat domestic sewage on ships that is flushed with fresh water or seawater. It ensures that the indexes of the treated discharged water meet the discharge standard of IMO.MEPC.227(64) and the standard of Type II device in 33CFR159.

This device is a patented product with independent intellectual property rights for independent innovation. The SWCM multi-stage marine sewage treatment device utilizes the principles of activated sludge, contact oxidation and membrane bioreactor (MBR) to decompose organic pollutants. The membrane bioreactor can treat sewage efficiently, thoroughly and cleanly, enabling the discharged water to meet the new IMO standards and other more stringent requirements.

Overview

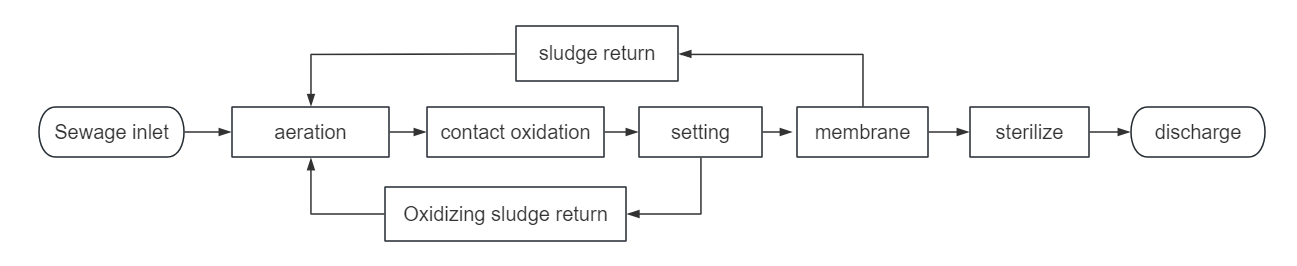

The process flow is as follows:

Main Technical Performance Table:

Model | SWCM(I)- | |||||||||||||||

15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 200 | 250 | 300 | 400 | ||

Load | Average load (L/d) | 1190 | 1540 | 1890 | 2310 | 3080 | 3780 | 4480 | 6020 | 7700 | 9100 | 11200 | 14700 | 18200 | 23100 | 30800 |

Peak load (L/h) | 149 | 193 | 237 | 289 | 385 | 473 | 560 | 753 | 963 | 1138 | 1400 | 1838 | 2275 | 2888 | 3850 | |

Organic load (kgBOD5/d) | 0.595 | 0.77 | 0.945 | 1.155 | 1.54 | 1.89 | 2.24 | 3.01 | 3.85 | 4.55 | 5. 6 | 7.35 | 9.10 | 11.55 | 15.4 | |

Rated capacity (men) | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 200 | 250 | 300 | 400 | |

Max capacity(men) | 17 | 22 | 27 | 33 | 44 | 54 | 64 | 86 | 110 | 130 | 160 | 210 | 260 | 330 | 440 | |

Electricity | AC 380V/50Hz/3φ, AC 415V/50Hz/3φ, AC 440, 60Hz/3φ, etc. | |||||||||||||||

Power (kW) | 2.5 | 2.5 | 2.5 | 2.5 | 3.0 | 3.0 | 3.5 | 4.0 | 4.0 | 4.0 | 6.0 | 6.0 | 7.0 | 9.0 | 11 | |

External dimension (mm) L×W×H | 1870 × 1200 × 1450 | 1680 × 1400 × 1570 | 1890 × 1400 × 1560 | 1980 × 1500 × 1650 | 2320 × 1600 × 1700 | 2320 × 1700 × 1880 | 2650 × 1700 × 1860 | 2800 × 1900 × 2090 | 2800 × 2100 × 2300 | 3030 × 2100 × 2300 | 3090 × 2250 × 2390 | 3640 × 2250 × 2390 | 3890 × 2450 × 2580 | 4790 × 2450 × 2600 | 5980 × 2450 × 2600 | |

Weight | Dry weight(kg) | 1000 | 1000 | 1100 | 1200 | 1300 | 1450 | 1600 | 1850 | 2200 | 2300 | 2800 | 3000 | 3300 | 3700 | 4200 |

Wet weight(kg) | 2283 | 2640 | 2740 | 3500 | 4400 | 5073 | 5270 | 6517 | 8268 | 9166 | 11340 | 13267 | 16538 | 20357 | 25417 | |

Effluent standard | BOD5≤25 Qi/Qe mg/L, COD≤125Qi/Qe mg/L, TSS≤35 Qi/Qe mg/L, coliform≤100/100ml, PH6~8.5, CL2≤0.5mg/L | |||||||||||||||

Major Accessories:

(1) Air Pumps

Air pumps are used to transport air to the device. The device is equipped with two types of air pumps, namely the main air pump and the lifting air pump. The main air pump is used for aerating the aeration tank and the contact oxidation tank, while the lifting air pump is used to lift the sludge in the membrane tank and the settling tank to the aeration tank and also for aerating the membrane tank.

(2) Cutting and Discharge Pumps

The cutting and discharge pumps are open impeller centrifugal pumps. Sewage is cut and crushed by the cutting pump so that it can be recycled or discharged overboard in emergency situations.

(3) Self-priming Pumps

The self-priming pump is a centrifugal pump with relatively strong self-priming ability. However, it is advisable to keep a certain amount of water in the pipes to avoid problems related to restarting. It can create a certain pressure difference to make water permeate through the membrane.

(4) Ultraviolet Sterilizers

The principle of ultraviolet sterilization is to adopt ultraviolet waves of appropriate wavelengths to damage the molecular structures of deoxyribonucleic acid (DNA) or ribonucleic acid (RNA) of biological cells, causing the death of growing cells and/or regenerative cells and making the content of coliform bacteria in the effluent meet the requirements of the discharge standard.

(5) Electric Control Boxes

The electric control boxes have the functions of electrical operation, protection and program control for the equipment.

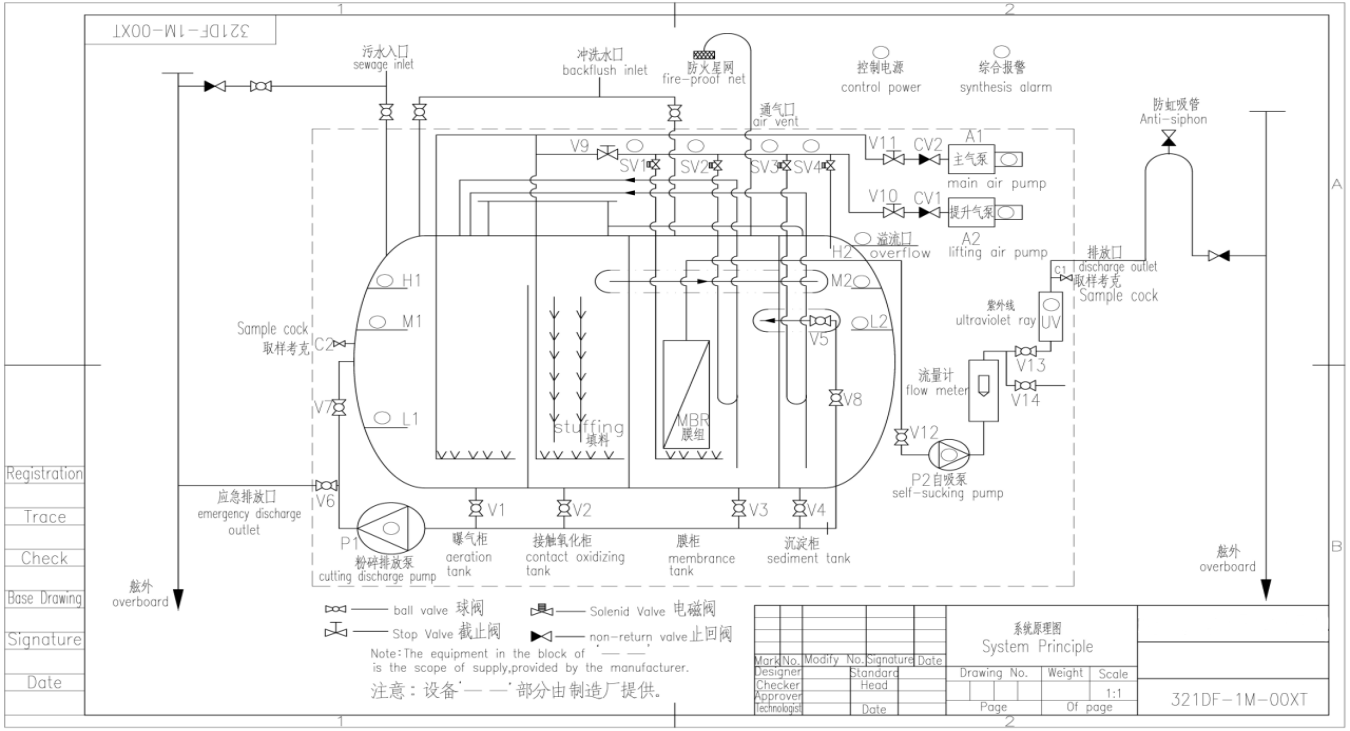

Principle diagram: