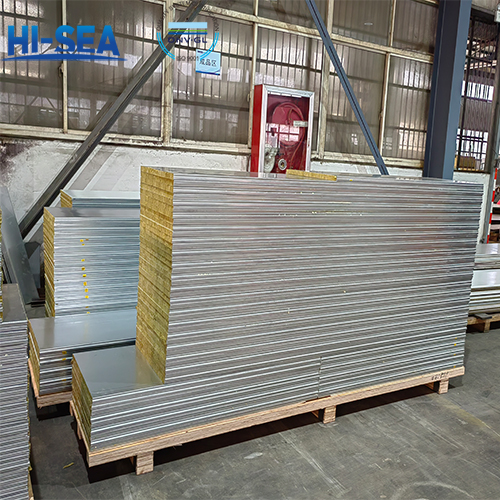

Marine Rock Wool Sandwich Panel

Rock wool sandwich panel is based on rock wool as the core board, and has the effect of thermal insulation and sound insulation. Generally speaking, under the same specifications, rock wool is better than the sound insulation of glass wool. Rock wool sandwich plate Metal sandwich plate composed of rock wool and metal steel plate by automatic equipment.

Overview

Advantages

Excellent fire performance

Rock wool sandwich panel using raw materials, production processes and formulations, so that it has good fire performance.

Good heat preservation and insulation

Rock wool sandwich panel thermal insulation performance is based on the thermal conductivity of rock wool = 0.043W / m² K, calculated on the basis of the thickness of the corresponding proportion of rock wool core material.

Sound insulation and sound absorption effect is remarkable:

Rock wool sandwich panel on the noise transmission has a significant role in reducing, especially suitable for designated flights through the place. In addition, the use of rock wool roof panels, rain, hail on the building roof steel impact caused by indoor sound, but also significantly weakened; rock wool sandwich panels at the same time has excellent sound absorption, it can absorb a relatively wide range of frequency range of sound.

Good rigidity

The overall steel is much better than the compression plate sandwich rock wool (glass wool) on-site composite panels. After the sandwich panel is fixed with purlin through connectors, it greatly improves the overall steeliness of the roof and strengthens the overall working performance of the roof.

Reasonable buckling method

Rock wool roof panel adopts buckle connection, avoiding the hidden trouble of water leakage of roof panel joints and saving the dosage of fittings.

Firm and reasonable fixing method:

Rock wool roof panel adopts special M6 self-tapping screws to fix with purlin, which can effectively resist the external force such as typhoon. The self-tapping screws are set in the crest position on the upper surface of the roof panel, and special waterproof construction is adopted to avoid waterproof weak point.

Short installation period

Rock wool sandwich panel, because the site without secondary processing, not only can keep the surrounding environment neat and clean, does not affect the normal conduct of other processes, but also can greatly shorten the installation cycle of the plate, rock wool sandwich panel of the daily average installation area of 600 ~ 800 square metres.

Picture of Marine Rock Wool Sandwich Panel