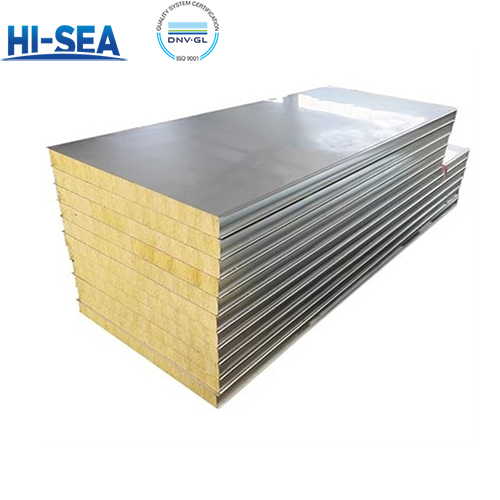

Marine Rock Wool Sandwich Board

Fire-proof Class: A60, A30, B15, B0

Thickness: 25mm/30mm/50mm/100mm

Width: 550mm

Length: Can be customized

Core Material: Rock Wool

Surface Finish: PVC Film/galvanized Steel Plate/Powder Painted/Stainless Steel/Aluminum Plate

Overview

Marine rock wool sandwich board is a kind of rock wool insulation board specially designed and used for ships, which has multiple advantages such as fireproof, thermal insulation, moisture resistance, corrosion resistance and environmental protection. This material is produced with a water-repellent additive, which gives it good moisture-proof performance and makes it especially suitable for use in such a humid environment as ships.

Structural Analysis: Why Choose Our Rock Wool Sandwich Panels?

Top/Bottom Panels: Optional galvanized steel sheet, stainless steel sheet, etc., with PVC film coating.

Core Rock Wool: Selected high-purity basalt, melted and centrifuged at high temperature to form fibers with uniform density.

High-Strength Adhesive: Uses environmentally friendly fire-retardant adhesive, compounded in one step on an automated continuous production line to ensure a strong bond.

Characteristics of Use

Marine rock wool sandwich boards are mainly used in ship construction for thermal and acoustic insulation of ships to improve their performance and comfort. In addition, marine rock wool boards have good corrosion resistance and can resist the erosion of seawater and chemicals, extending the service life of ships. Due to its environmental performance, marine rock wool boards also meet the environmental requirements of modern ship construction, reducing the negative impact on the environment.

Picture of Marine Rock Wool Sandwich Board