Marine Hydrophore Unit

Technical Specification

Working Pressure: 0.4MPa

Design Pressure: 0.44MPa

Test Pressure: 0.66MPa

Design Temperature: 50 ℃

Volume: 1.0 m³

Import and Export Flange: 6040 GB/T 2506-2005

Classification: LR

Medium: Fresh Water

Surface Treatment:

The inner surface sand blasting for derusting reaches Sa2.5 level, the inner surface is coated with non-toxic epoxy coatings;

the outer surface is coated with anti-rust and white paints.

As a professional supplier of ship equipment, we have rich project experience and can offer you excellent solutions and after-sales experiences. If you have a purchasing plan for marine hydrophores or related inquiries, please do not hesitate to contact us! Email <hs10@cqhisea.com>

Overview

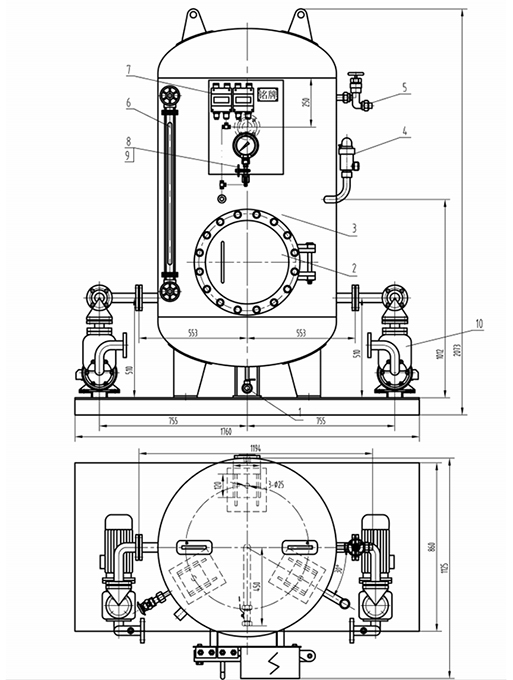

Structure Diagram

Main structure

Main Body: The main body of the marine pressure water tank serves as the container to hold the water and provides the overall structure and support for the entire system.

Safety Valve: The safety valve is crucial for protecting the pressure water tank from overpressure. When the pressure inside the tank exceeds a preset safe limit, the safety valve opens to release the excess pressure and prevent potential damage or explosion.

Air Valve: The air valve is responsible for allowing air to enter or exit the tank as needed. It helps maintain the proper pressure balance within the tank and ensures smooth operation of the water supply system.

Liquid Level Indicator: The liquid level indicator provides a visual indication of the water level inside the tank. This allows operators to monitor the water volume and take appropriate actions to refill or control the usage as necessary.

Pressure Controller: The pressure controller regulates and maintains the desired pressure within the pressure water tank. It senses the pressure and controls the operation of associated components to keep the pressure within the specified range.

Pressure Gauge: The pressure gauge measures and displays the actual pressure inside the tank. It provides real-time pressure information for operators to monitor and assess the system's performance.

Pump: The pump is used to pressurize the water and ensure a continuous and adequate supply of pressurized water from the tank to the various systems or equipment that require it.

Conclusion

Finally, thank you for browsing the full text, I hope you have a more profound understanding of Marine Hydrophore. For more knowledge and products about pressure tanks, please visit our Marine Hydrophore website home page or contact us directly!