Marine Hydrophore Tank

Marine Hydrophore Tank, functioning as either the freshwater tank or the sanitary water tank on ships, supplies domestic water or cleaning water for vessels. It can also be matched with air compressors to serve as pressure water supply equipment for the superstructures of ships.

This tank plays a crucial role in ensuring the smooth operation of daily life and cleaning activities on board. The freshwater it stores is essential for drinking, cooking, and personal hygiene of the crew and passengers. The sanitary water it provides is indispensable for cleaning various compartments and equipment.

When combined with air compressors, the Marine Hydrophore Tank becomes an efficient pressure water supply system, guaranteeing a stable and adequate water supply to the upper parts of the ship. This helps meet the water demands for different facilities and systems, contributing to the overall comfort and functionality of the ship's living and working spaces.

As a professional supplier of ship equipment, we have rich project experience and can offer you excellent solutions and after-sales experiences. If you have a purchasing plan for marine hydrophores or related inquiries, please do not hesitate to contact us! Email <hs10@cqhisea.com>

Overview

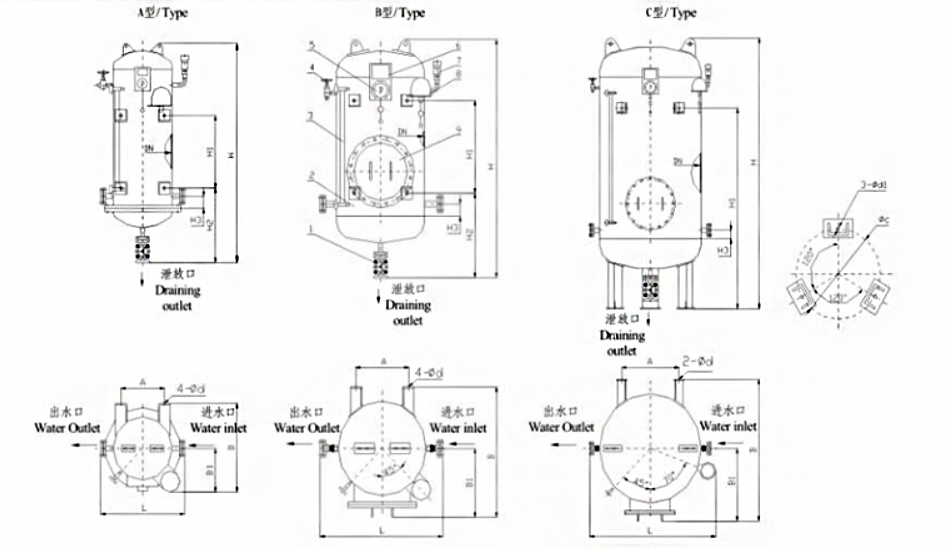

Structure Type

Component Introduction

Main body: The main body of the marine pressure water tank serves as a container for storing and holding water, providing the basic structure and support for the entire system.

Stop valve: The stop valve is used to control the flow of water in the pipeline. It can be opened or closed by rotating the valve stem and can effectively cut off the water flow for maintenance, component replacement, or control of the water flow.

Liquid level gauge: The liquid level gauge is used to visually display the water level height inside the pressure water tank, enabling operators to understand the water volume in the tank in real-time so that measures such as adding water or draining water can be taken in a timely manner.

Stop-check valve: The stop-check valve can both cut off the water flow like a stop valve and prevent the backflow of water, ensuring that the water flows in the predetermined direction in the pipeline and protecting the system from the influence of reverse water flow.

Pressure gauge: The pressure gauge is used to measure and display the pressure value inside the pressure water tank, helping operators monitor the pressure status and ensuring that the pressure operates within a safe and normal range.

Safety valve: The safety valve automatically opens when the pressure inside the pressure water tank exceeds the set safety limit, releasing the excess pressure, protecting the water tank and the entire system from damage due to excessive pressure, and preventing possible explosions or malfunctions.

Pressure controller: The pressure controller is used to regulate and maintain the desired pressure inside the pressure water tank. It can sense pressure changes and control the operation of related equipment to keep the pressure within the specified range.

Manhole cover: The manhole cover provides access to the inside of the pressure water tank, facilitating inspection, cleaning, and maintenance work, while maintaining the sealing of the water tank during normal operation.

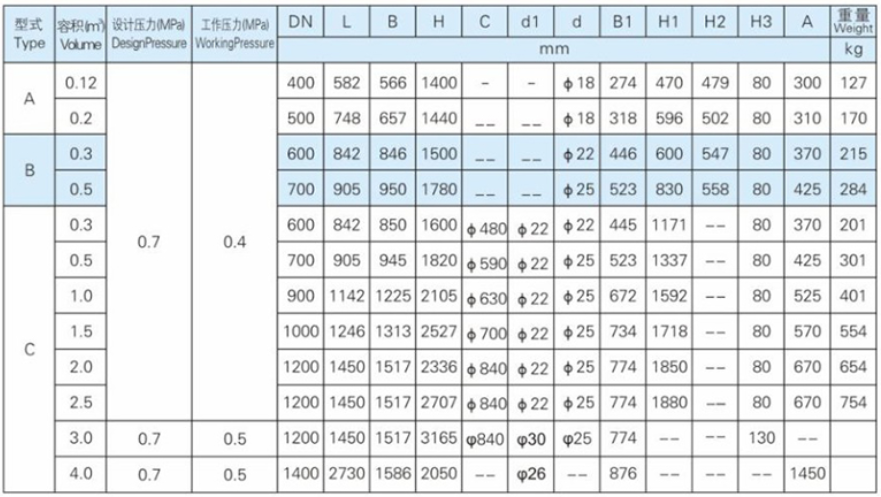

Technical Parameter

Conclusion

Finally, thank you for browsing the full text, I hope you have a more profound understanding of Marine Hydrophore. For more knowledge and products about pressure tanks, please visit our Marine Hydrophore website home page or contact us directly!