Marine Heavy Fuel Oil Separator

In the shipping industry, heavy oil is often used as the economic fuel for ships. However, heavy oil contains moisture and impurities. If it is directly supplied to the ship's main engine and auxiliary engines without treatment, it will cause serious potential safety hazards.

Marine oil separators are important equipment for purifying heavy oil. According to factors such as the size of the ship and the amount of oil used, several sets are generally installed. It is determined whether to separate water or residue according to the content of water and residue in the oil, and whether to work alone or in series or in parallel. Generally, when the heavy oil separator has more residue in the fuel, it works in the order of series and separating water first and then residue. The oil separator distributes the fuel from the settling tank to the daily use tank.

As a professional supplier of ship equipment, we have rich experience in solving the purification of fuel oil and lubricating oil. If you have such needs, please be sure to contact us by email <hs10@cqhisea.com>!

Overview

Basic Principle

Unpurified and unseparated heavy fuel oil is composed of pure oil, moisture and mechanical impurities, and their densities are different. Among them, the density of pure oil is the smallest, the density of mechanical impurities is the largest, and the density of moisture is in the middle.

When the fuel is placed in a high-speed rotating separation drum, the fuel rotates at a high speed along with the separation drum, and the pure oil, moisture and mechanical impurities in the fuel are then in the centrifugal force field. Just like sedimentary separation using the gravitational field, the centrifugal inertial forces generated by oil, water and mechanical impurities are different, and they will be layered along the direction of the centrifugal force.

The centrifugal inertial force of mechanical impurities is the largest and remains in the outermost ring of the separation drum; the centrifugal inertial force of pure oil is the smallest and gathers near the rotating shaft; and the moisture is located between the two. The centrifugal inertial forces of mechanical impurities, moisture and pure oil are several thousand times larger than their own gravity. Using a centrifugal oil separator can shorten the fuel purification time and improve the purification effect.

Introduction of the main component structures

Separator drum: This is the core component, usually made of high-strength materials, and there are elaborately designed spaces and channels inside to achieve the separation of fuel.

Driving device: Generally includes a motor or other power sources, which drives the separator drum to rotate at high speed through the transmission mechanism.

Fuel inlet system: Includes the fuel inlet pipe, fuel pump, etc., and is responsible for accurately sending the unpurified heavy oil into the separator drum.

Fuel outlet system: Includes the pure oil outlet and impurity outlet, etc. The pure oil outlet is used to discharge the purified fuel, and the impurity outlet is used to discharge the separated mechanical impurities and moisture.

Control system: It is used to monitor and adjust the working parameters of the oil separator, such as the rotation speed and separation time, to ensure the best separation effect.

Base and support structure: It provides stable support for the entire oil separator to ensure its stability during operation.

Sealing device: To prevent fuel leakage and ensure the sealing and safety of the equipment.

Monitoring device: Such as pressure sensor, temperature sensor, etc., which is used to monitor the working state of the oil separator in real time to discover abnormal situations in time.

Slag discharge mechanism: After a certain period of time, it is responsible for discharging the impurities accumulated in the separator drum to ensure a continuous separation effect.

Adjustment mechanism: It can fine-tune some parameters of the oil separator according to different fuel properties and work requirements to adapt to various working conditions.

There may be certain differences in the specific structures of different types and models of heavy oil separators, but generally they all include these main components, and they work together to achieve efficient purification and separation of heavy oil.

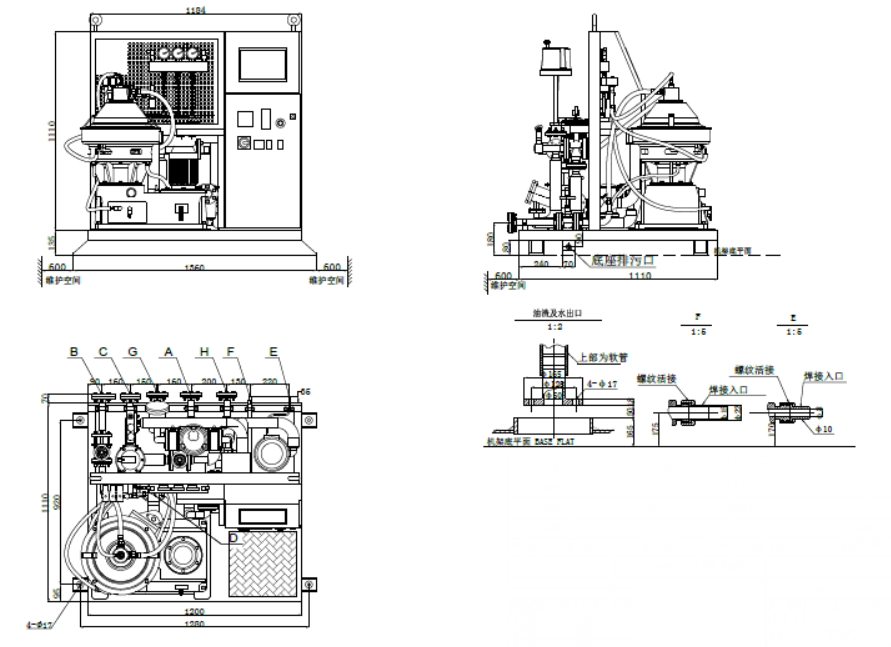

Structure Drawing

Conclusion

By browsing this article, we believe that you must have a certain understanding of our oil separator. If you have procurement needs or want to learn more about the details or parameters in depth, welcome to visit the homepage of our marine oil separator, or contact us directly!