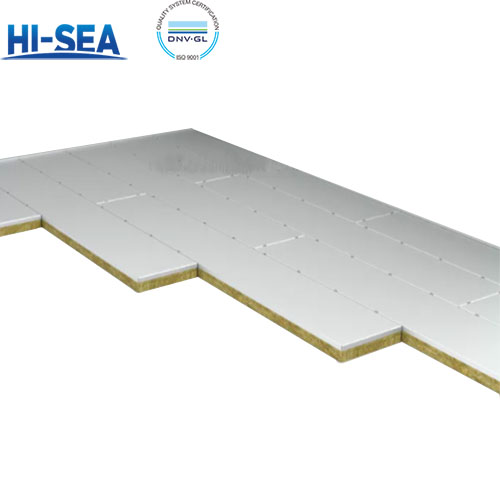

Marine Floating Floor

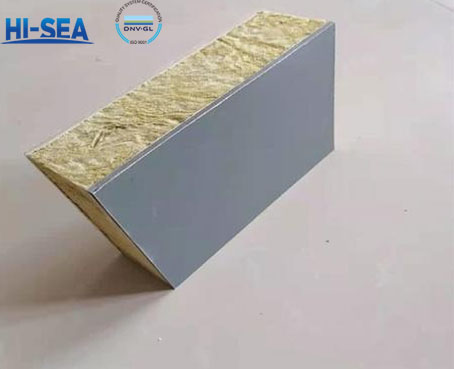

Marine floating floors are made of 50mm lightweight fire insulation material rock wool as the bottom layer, the upper layer in turn laying 3mm and 2mm thick galvanized steel plate (the middle of the use of 1mm thick damping adhesive bonding) combined into a floating deck structure. Floating floor is mainly used in the local (A60 class fire requirements) cabins of ships, with excellent vibration damping, noise reduction, acoustic insulation, heat insulation function.

Overview

Introduction:

Marine Floating Floor comprises: a base layer, which is laid on top of the deck of a ship; a floating layer, which is laid on top of said base layer, and said floating layer forms a predetermined thickness and has flexibility to isolate noise and absorb vibration; and a support layer, which is laid on top of said floating layer to reinforce the flexible floating layer.

Marine Floating Floor has a good ability to resist vibration and isolate noise, thus enhancing the comfort of passengers, and also providing a good working environment for the staff, protecting the staff from vibration or noise and avoiding operation errors, thus ensuring the normal and safe operation of the ship.

Fire Class: A60

Size: Width300mm, Length1970mm

Weight: 39Kg/㎡, 60mm insulation

Steel Plate: 3mm Steel

Picture:

Fire Class | A-60 |

Dimension | 450mm Width(Max) 1230mm Length (Max) |

Weight | 125.6kg/m²(47.1Kg/m² Floating floor+78.5Kg/m² Deck |

Thermal transmittance | 0.49Kcal/m²h℃ |

Tolerances | Width°-1*Length±1*Thickness°-1 |

Combination sound reduction | 51~54dB |