Marine Flanged Stainless Steel Globe Valve

The working principle of Marine Flanged Stainless Steel Globe Valve is to rely on the torsion of the valve stem to give a downward pressure to the sealing surface, so that the sealing surface of the disc is closely attached to the sealing surface of the valve seat, thus preventing the inflow of medium or adjusting the flow rate of medium.

Overview

Features:

Exquisite material: Marine flanged stainless steel globe valves are usually made of 304 stainless steel, which is not only corrosion-resistant, but also adaptable to acid and alkali media and suitable for various harsh marine environments.

Wide application range: it is suitable for cutting off or connecting pipeline media in petroleum, chemical industry, ships, thermal power plants and other systems with nominal pressure pn 1.6 ~ 16.0 MPa and working temperature ≤-29℃ ~ 550℃.

Good sealing performance: high hardness, wear resistance, high temperature resistance, corrosion resistance, good scratch resistance and long service life.

Simple structure: the disc moves linearly along the center line of the valve seat, which is simple in structure and convenient to manufacture and maintain.

Various applicable media: suitable for seawater, oil, steam, acid, alkali, ammonia, urea, sulfur-containing natural gas and other media.

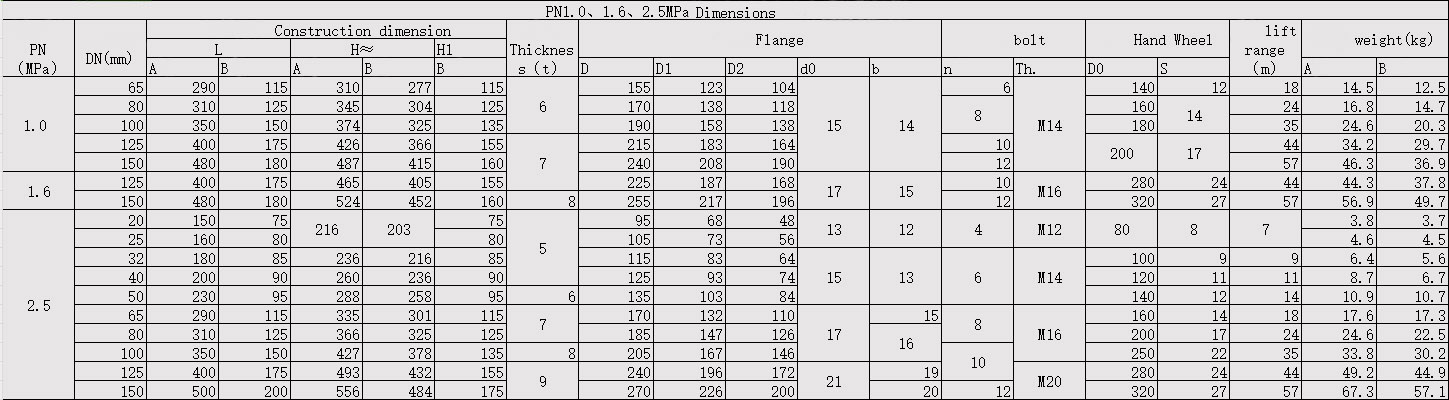

Paramenters: