Marine Flanged Stainless Steel Angle Globe Valve

Material:SS304 SS316 SS316L, etc.

Specifications: DN15-DN600.

Standard: GB,CB.

Pressure: 1.0Mpa~6.4Mpa.

End Connection: Flanged.

Working Temperature: -160~550℃

Medium: Water, Oil, Gas Nitric Acid, etc.

Overview

Installation:

1. Before installation, ensure that the gap between the valve and the pipeline is clean, and ensure that there are no impurities or residues in the pipeline.

2. According to the size of the pipeline to choose the appropriate flange stop valve.

3. Place the valve in a proper position and ensure that the valve is closed.

4. Connect the valve with the flange of the pipeline with the flange sealing gasket. Ensure that the gasket will not be squeezed or deformed when tightening the bolt.

5. Tighten the bolts with an appropriate wrench or wrench to ensure that the valve is firmly connected with the flange of the pipeline.

6. After installation, check the sealing performance of the valve. Check whether there is leakage between the valve and the pipeline.

7. If there is any leakage, try to retighten the bolt or replace the gasket to solve the problem.

8. After the installation, test the switch function of the valve as needed, and ensure that the valve can work normally.

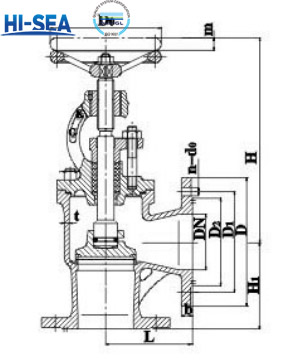

Drawing:

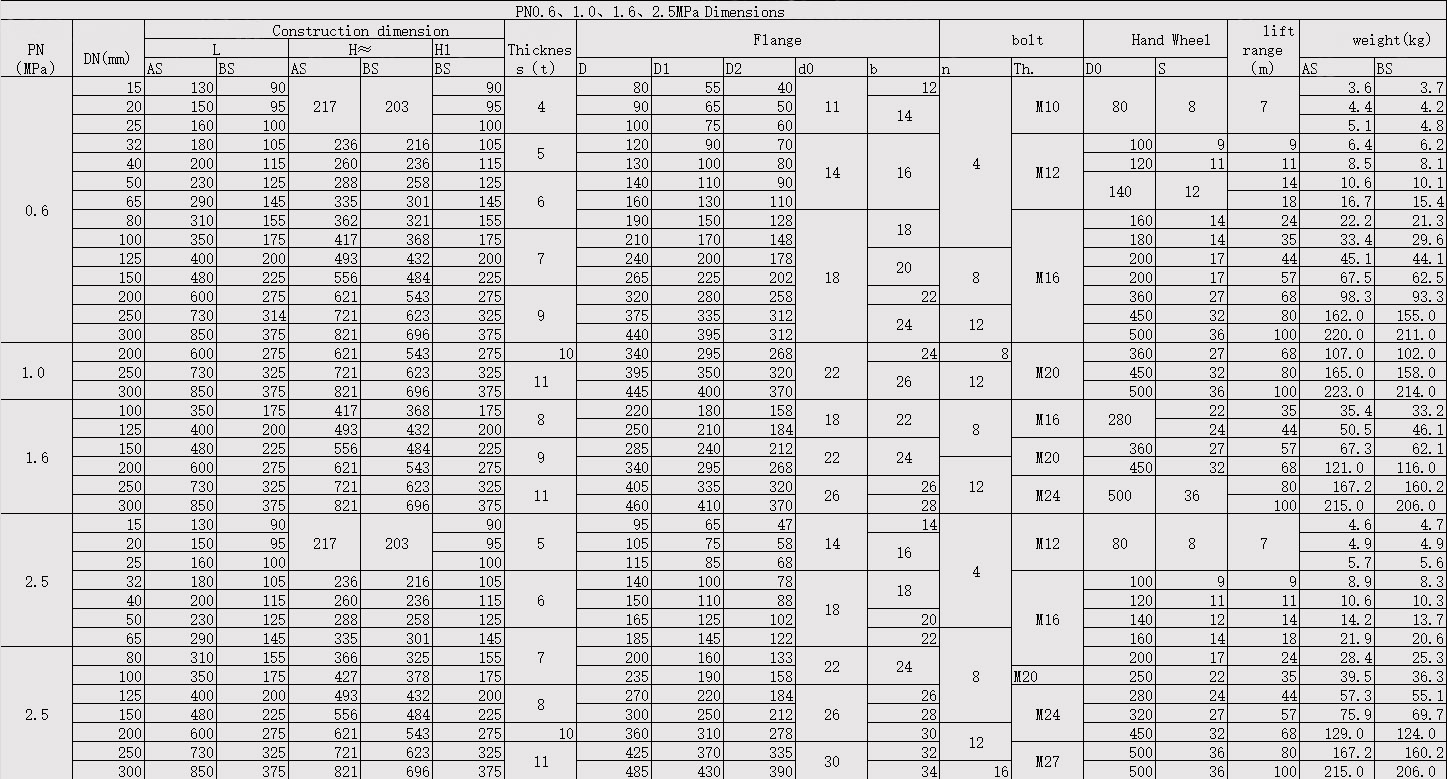

Parameters: