Marine Explosion Proof Centrifugal Fan

Marine explosion proof centrifugal fan is essentially a variable flow constant pressure device. The theoretical pressure-flow curve of a centrifugal fan should be a straight line when the rotational speed is constant. Due to internal losses, the actual characteristic curve is curved. The pressure generated in a centrifugal fan is strongly influenced by changes in inlet air temperature or density. For a given inlet volume, the lowest pressure is generated at the highest inlet temperature (lowest air density). For a given pressure vs. flow characteristic curve, there is a power vs. flow characteristic curve. When the blower is operated at a constant speed, for a given flow rate, the required power increases as the inlet temperature decreases.

Overview

Tips for use:

When starting a marine fan, if there is a start-up failure or excessive start-up time, there are a number of reasons for this. If the motor is not dragging, check the settings of the safety mechanism; if the motor rating is too low, replace the motor; if the starting procedure is incorrect, adjust the starting equipment; if the power consumption is excessive when starting, verify that the gas flow control mechanism is in the off position when starting.

If the rotor is stuck, pan the fan by hand to check and investigate the cause of the sticking (friction, obstruction, etc.); if the voltage is too low at the motor's wiring, check the power line voltage and increase the power line if the loss is too great.

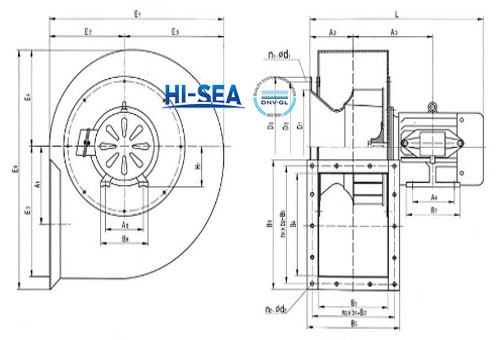

Drawing:

Picture: