Marine Evaporative Desalination System

The marine evaporative desalination system utilizes the waste heat of the cooling water from the marine diesel engine as the heat source and adopts the method of high vacuum and low-temperature boiling distillation to produce fresh water from seawater.

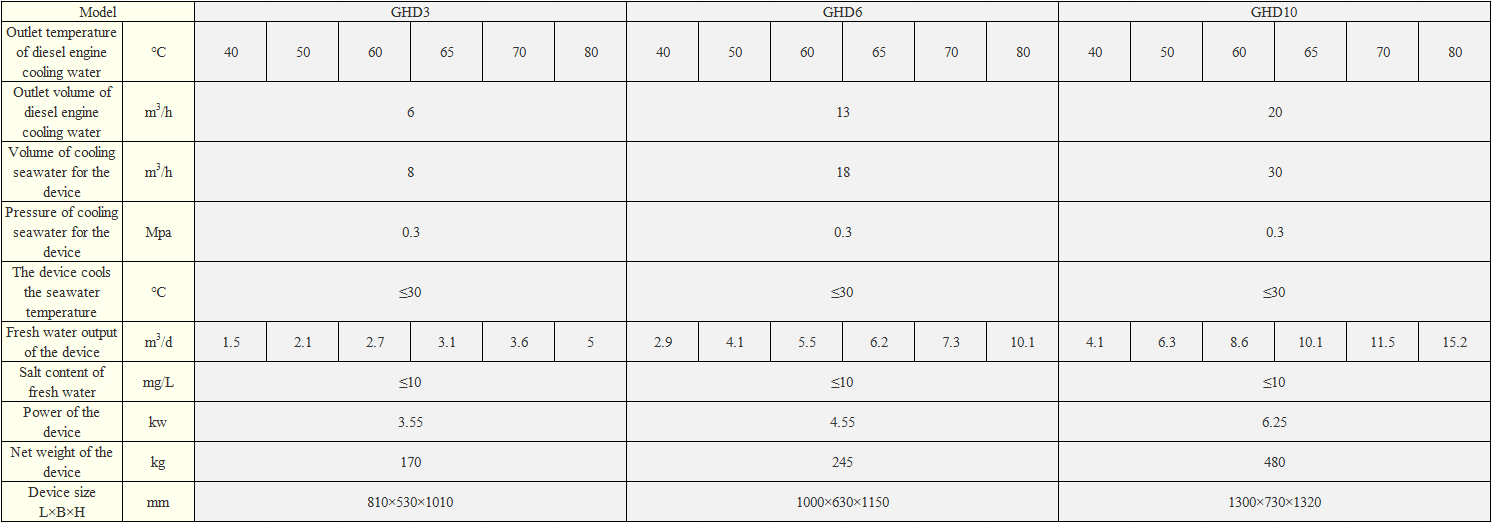

This device currently has three models with daily fresh water production capacities of 3 tons, 6 tons, and 10 tons, namely GHD3 type, GHD6 type, and GHD10 type. For each model, depending on the power of the diesel engine, that is, the size of the waste heat source of the cooling water, the amount of fresh water produced has a range. The GHD3 type is 1.5 - 4 tons/day, the GHD6 type is 5 - 7 tons/day, and the GHD10 type is 8 - 12 tons/day.

The fresh water produced by this device can be used for drinking, boiler feed water, diesel engine cooling fresh water, ice making, etc. After using this device, the volume of the fresh water tank on the ship can be reduced, the volume of the fuel tank can be increased, and the endurance capacity of the ship can be improved.

This device is mainly made of stainless steel and copper alloy materials. It has a novel structure, is highly efficient, energy-saving, small in size, light in weight. The heater can prevent and remove scale. The operation is simple, the installation and maintenance are convenient, and it is economical and practical. Contact email <hs10@cqhisea.com>

Overview

Product model and main technical parameters

Working Principle

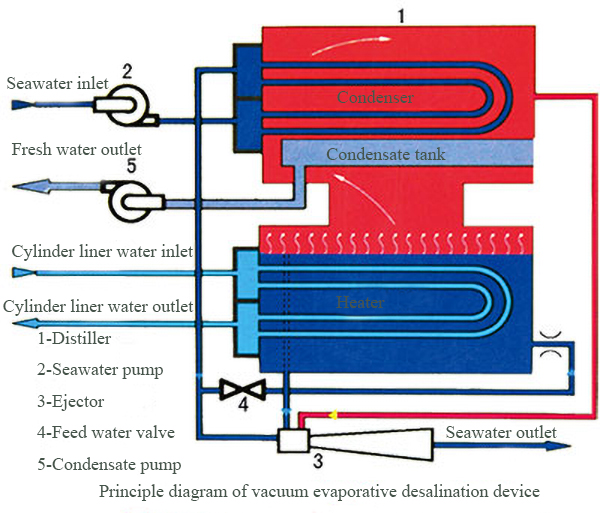

This device uses the waste heat of the diesel engine cylinder liner cooling water to heat the seawater. Under high vacuum and low-temperature conditions, through processes such as boiling, separation, and condensation, the seawater is distilled into fresh water. See the schematic diagram. The seawater desalination distiller has a heater at the lower part and a condenser and condensate tank at the upper part. Around the distiller, there are seawater pumps, water ejection extractors, feed water valves, and condensate pumps. The process of distillation for freshwater production is as follows:

1.Vacuuming and extracting salt water

The high-pressure seawater from the seawater pump flows through the condenser tube bundle. At the outlet pipe of the condenser, there is a tee. One path flows through the water ejection extractor. The kinetic energy transformed from the pressure energy of the seawater is used to suck the air and uncondensed steam in the upper part of the distiller to achieve a high vacuum degree in the distillation chamber. At the same time, the concentrated salt water from the lower heater is extracted. The other path flows to the feed water valve, which continuously supplies a regulated amount of seawater to the heater to maintain the balance of the seawater level.

2.Heating the seawater for boiling and distillation to produce fresh water

The above-mentioned seawater continuously supplied outside the heater tube bundle has been preheated in the condenser. The cylinder liner cooling water of the diesel engine flowing in from the upper opening of the heater transfers heat to the seawater outside the tube bundle within the tube bundle. The temperature of the seawater gradually increases from bottom to top and from right to left. Under high vacuum, that is, below -0.093 Mpa, and at a relatively low seawater temperature, that is, above 35℃, boiling distillation occurs. The steam rises to the condenser, condenses into distilled water, gathers in the condensate tank, and is then extracted by the condensate pump, thereby continuously producing fresh water from the seawater.

Conclusion

Marine seawater desalinators are essential equipment for ships and offshore platforms. The importance of them as the source of working and living water is self-evident. If you have relevant needs, please visit our homepage of marine seawater desalination plants or contact us directly!