Marine Electric Double Gypsy Anchor Windlass

The electric double gypsy anchor windlass is a main deck machinery used on ships to raise and lower the anchor. It typically featured two gypsy wheels, allowing two separate anchor chains to work independently with the electric motor driven. It offers efficiency for anchoring. According to different size of ships, the windlass can be designed in different size. An emergency stopping mechanism can be equipped on the anchor windlass to cut off the power of it in case special circumstances happen.

1. Power by electric motor, with double sprocket

2. Single-speed, double speed or three-speed

3. Easy for operation and maintenance

4. Overload protection, emergency stop buttons

Overview

Electric double gypsy anchor windlass is one of the most essential mechanical device on ships. It is is a valuable addition to any vessel, enhancing the anchoring process's efficiency and safety. It consists of the double chain wheel, electric motor, gearbox, brake and clutch system, control system, etc.

Electric motor: The power source of the windlass. It converts electrical energy into mechanical energy to drive the rotation of the chain wheel. It can be classified into the variable frequency motor and the fixed frequency motor. The fixed frequency motor can achieve single-speed, double-speed, and three-speed.

Double Chain Wheel (Gypsy Wheel):This is a key component of the windlass. It consists of two chain wheels, usually made of high-strength steel with good wear resistance and corrosion resistance. Each sprocket is matched with the anchor chain, and the retraction of the anchor chain is achieved through the rotation of the sprocket.

Reducer: Generally, gearboxes or worm gears are used to reduce the high speed of the electric motor to a low speed suitable for anchoring and lowering, while increasing torque to enable the anchor windlass to generate sufficient force to retract the anchor chain.

Clutch and brake system: The clutch is used to connect or disconnect the sprocket from the drive shaft, allowing for individual control of the rotation of each sprocket when needed. The braking system is used to fix the sprocket to prevent accidental rotation and ensure the safety of the ship when anchored. It usually uses belt brakes or disc brakes, which are easy to operate and reliable in braking.

Control System:This is the brain of the anchor windlass, which allows the operator to control the operation of the windlass. It typically includes local control panels installed on the ship's deck and may also have remote control capabilities, enabling operation from the ship's bridge or other convenient locations. The control system allows for precise control of the speed and direction of the windlass, as well as monitoring of its operating status, such as load levels and motor temperature.

Features

Electric motor: fixed frequency motor or variable frequency motor

Single-speed, double speed or three-speed

Equipped with two sprockets

Manually or hydraulically operated brake and clutch

Warping head: none, single or double

Local control or remote control

Reliable service, long lifespan

Excellent operation, high efficiency

Can be customized as per user’s requirement.

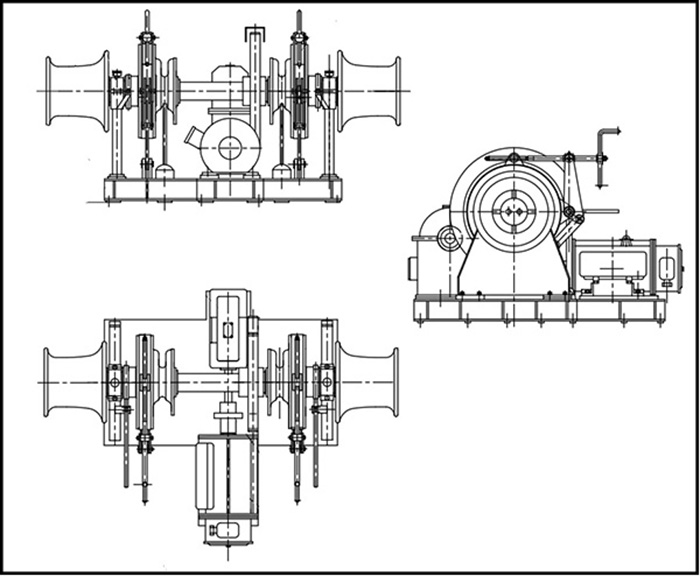

Drawing for Marine Electric Double Gypsy Anchor Windlass

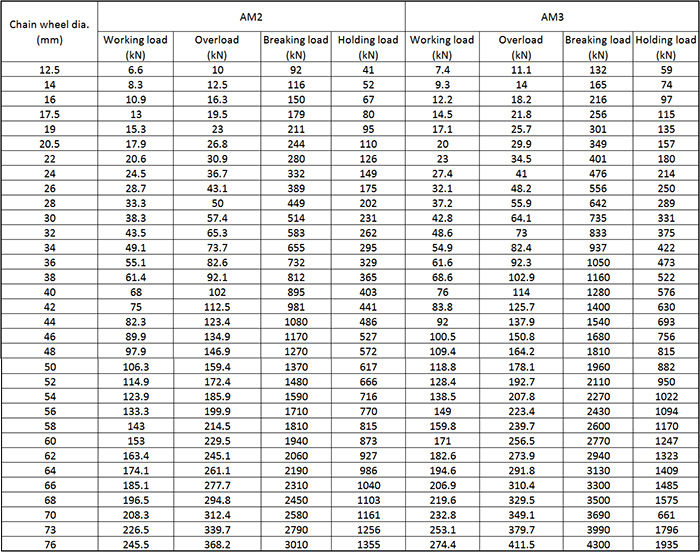

Main Technical Parameter