Marine Diesel Powered Double Sprocket Anchor Windlass

Marine Diesel Powered Double Sprocket Anchor Windlass is an essential tool for marine operations, providing the necessary power and control for safe anchoring. Its design and functionality cater to the demanding requirements of various marine applications. This marine anchor windlass, is powered by a diesel engine, features two gypsy heads for handling two separate chains.

1. Driven by the diesel engine

2. Reasonable compact structure design

3. Large torque and good stability

4. Compact structure with high strength

5. Manually operated barke & cluth

Overview

Marine Diesel Powered Double Sprocket Anchor Windlass is a specialized piece of equipment used on boats and ships to handle anchors. This marine anchor windlass, is powered by a diesel engine, is the machine that restrains and manipulates the anchor chain on a boat, allowing the anchor to be raised and lowered by means of anchor chain. There are two primary drive configurations. Type 1 utilizes the engine to drive the windlass through a transmission gearbox and worm gear. Type 2 involves the engine powering a hydraulic power unit, which in turn drives a hydraulic motor to operate the windlass. It is directly driven by a diesel engine through a shaft. Engine-driven anchor windlass are a key focus of our product line, especially for use on barges.

Features & characteristics

Reasonable compact structure design

Driven by the diesel engine

Perfect starting and working efficiency

Large torque and good stability

Raising and Lowering the Anchor

Manually operated brake and clutch

Corrosion-resistance, high quality

Easy installation, easy and safe operation

Can be customized as per user’s requirements

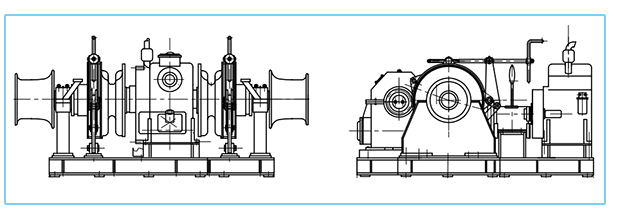

Drawing for Marine Diesel Powered Double Sprocket Anchor Windlass

Main technical specifications(only for reference)

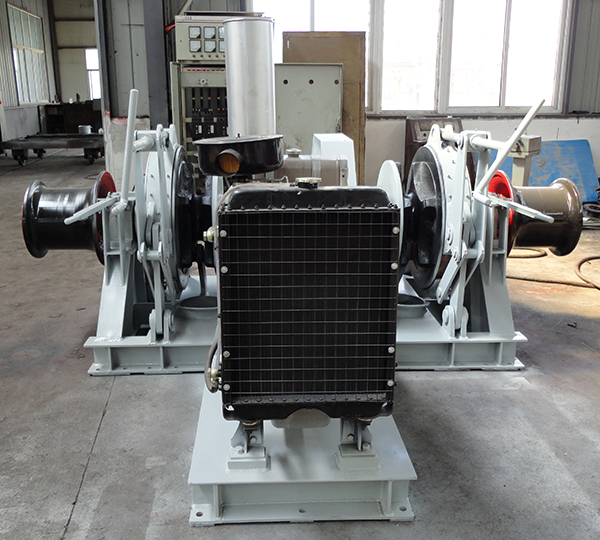

Marine Diesel Powered Double Sprocket Anchor Windlass in Factory

Maintenance advice

★ The mechanical part of the machine should work under good lubrication conditions. The machine should be idling for a moment after each refueling to allow the grease to evenly coat the running surface.

★ Refueling parts are butter nozzle, transmission rod, gear, brake lever, etc.

★ The machine body and fixing bolts should be checked frequently for completeness and tightness. The brakes of the machine should be checked regularly to prevent grease from adhering to the braking surface. When the brake belt rivets rub against the brake hub, the brake belt should be replaced in time.

★ What is the condition of the limit bolts (adjustment bolts) of the windlass brake belt? Is it rusted? Special attention should be paid to the screw teeth under the brake lever, that is, after the brake is tightened, check the remaining screw teeth under the brake lever. According to previous experience, there are at least 10 teeth to be assured. The limit bolt is between the brake lever and the brake band, which can be used to adjust the height of the brake lever. The thread of the limit screw is fine. Open the brake lever and slowly adjust the limit bolt until the thread under the brake screw meets the requirements. This bolt should be properly buttered, wrapped in tarpaulin, and checked at least every three months.