Marine Biological Sewage Treatment Plant

This Marine Biological Sewage Treatment Plant is used to handle the fecal sewage (also known as black water) from toilets on ships. During the treatment process, no dilution water, gray water, treated water and/or sea water are added. It is not applicable to passenger ships that discharge domestic sewage in special areas (referring to the Baltic Sea), and the requirements for total nitrogen and total phosphorus performance indicators are not considered.

Marine domestic sewage treatment device belongs to the key equipment of the IMO International Convention for the Prevention of Marine Pollution from Ships "MARPOL 73/78" Annex IV. This series of biological domestic sewage treatment devices comply with the MEPC.227(64) resolution (called the new standard) promulgated on October 5, 2012.

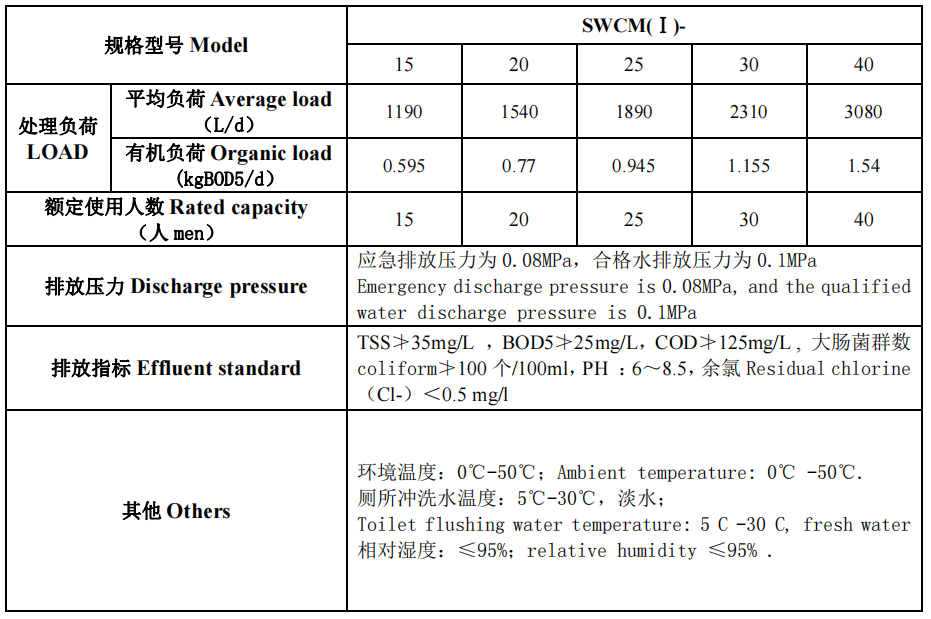

This series belongs to a small domestic sewage treatment device and is suitable for ships with the number of personnel ranging from 10 to 40. Of course, as a leading domestic supplier, we can also provide large-scale domestic sewage treatment equipment to meet your needs. If you have a procurement demand in this regard, please visit the homepage of our marine domestic sewage treatment device, or directly contact us by email!<hs10@cqhisea.com>!

Overview

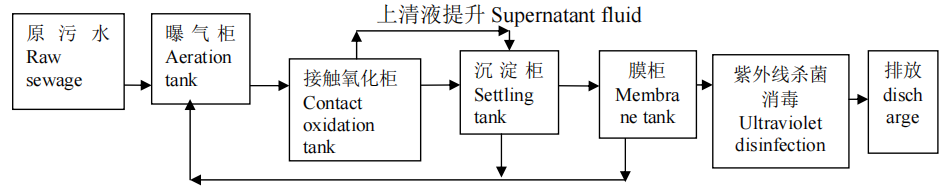

System principle

This device and treatment process comprehensively utilize biological treatment technology, electrocoagulation technology, membrane separation technology and ultraviolet disinfection technology. By rationally arranging the treatment process and strengthening the combination of flocculation and biochemical treatment, it overcomes the inherent deficiencies of the existing membrane bioreactor, and makes breakthroughs in stabilizing the effect of nitrogen and phosphorus removal, enhancing sludge activity and preventing membrane pollution. Its treatment process is as follows:

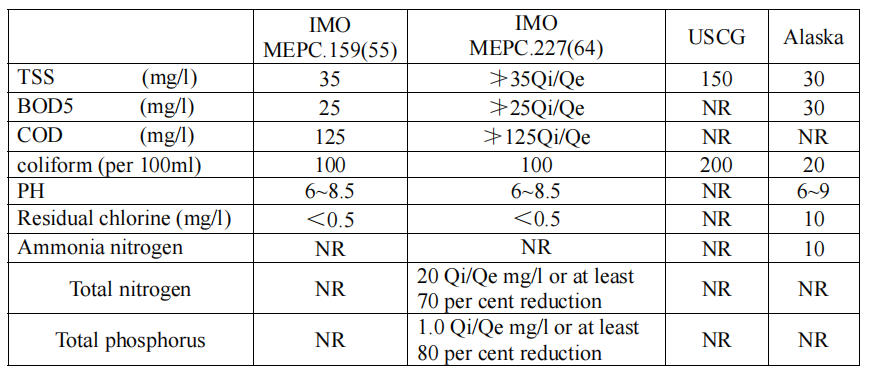

Standards

This device will be applicable to the domestic sewage treatment devices installed on the following ships on or after January 1, 2016:

(1) Ships in almost all areas;

(2) Passenger ships outside the special area of MARPOL Annex IV.

Summarize various rules and emission standards as follows:

Specifications and Main Parameters

Main spare parts

Air pump

The air pump is used to supply compressed air to the device, so as to aerate the aeration tank, the contact oxidation tank and the membrane tank, and to lift the supernatant in the contact oxidation tank to the sedimentation tank and to lift the sludge in the membrane tank and the sedimentation tank to the aeration tank.

Crushing and discharging pump

The crushing and discharging pump is a centrifugal pump with a cutter, which is used for the cyclic crushing of sewage to make the pulped sewage easy to be decomposed; in the case of discharging sludge or in an emergency, the sewage can also be directly discharged overboard; or when cleaning the tank body, the sludge and sewage in each tank can be emptied, and at this time, only the corresponding bottom valves of each tank need to be opened.

Self-priming pump (vacuum pump)

The self-priming pump has a relatively strong self-priming ability, but during normal operation, it is best that the suction pipe of the self-priming pump cannot be dehydrated to avoid difficulty in starting next time. The self-priming pump can form a certain pressure difference inside and outside the membrane filament, so that the water can permeate through the membrane and be discharged. If the membrane is clogged due to pollution and the suction is not smooth, the drainage volume will decrease, and eventually cause a high water level alarm of the device.

Ultraviolet disinfector (UV)

The main disinfection principle of the ultraviolet disinfector is to use the ultraviolet rays released by the ultraviolet lamp tube inside it to destroy the molecular structure of DNA (deoxyribonucleic acid) or RNA (ribonucleic acid) in the microbial cell body, causing growth cell death and/or regenerative cell death, so that the coliform group meets the discharge standard.

Electrocoagulation reactor

In addition to carrying out redox reaction after the end of biochemical treatment to further degrade the organic matter in the water, the electrocoagulation reactor also performs coagulation function to enhance the sedimentation performance of the sewage, remove phosphorus and colloid in the sewage, and improve the operating environment of the MBR membrane.

Electrical control box

The electrical control box is used to realize the functions of automatic control, protection and program control of the device.

Conclusion

For additional details, please contact us! For other types of products, please feel free to contact us, or visit our Marine Sewage Treatment System homepage to learn more!