Marine Angle SNDR Valve

The Marine Angle SNDR Valve is mainly used on ships to ensure that the flow direction of the fluid can be effectively controlled during the operation of the ship, to prevent the fluid from flowing backwards, and to protect the equipment and pipeline system from being damaged.

Overview

Application:

Ship pipeline system: Because ship valves need to bear complex pressure and bending loads, angle stop check valves are suitable for ship pipeline system to meet various fluid control requirements.

Maintenance suggestion:

Regular inspection: check the sealing performance and operation flexibility of the valve regularly to ensure that the valve is in good working condition.

Lubrication and maintenance: properly lubricate and maintain the valve to reduce friction and wear.

Prevent blockage: regularly clean impurities and blockages in the valve to ensure smooth flow of fluid.

Material selection:

Stainless steel: stainless steel materials such as 304, 316 and 316L have excellent corrosion resistance and high strength, and are especially suitable for corrosive media such as seawater.

Cast iron: It has good castability and corrosion resistance, but its strength is low, so it is suitable for occasions with low pressure.

Cast steel: it has high strength and corrosion resistance, can withstand high pressure and temperature, and is suitable for high pressure and high temperature systems.

Brass: It has good corrosion resistance and sealing performance, and is often used for valve discs and seats.

Rubber: In some types of marine stop check valves, it is used as a seal to improve the sealing performance of the valve.

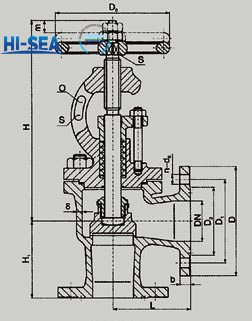

Drawing: