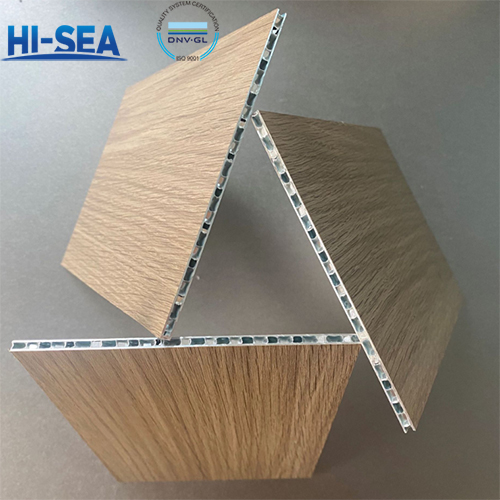

Marine Aluminum Honeycomb Sandwich Panel

Honeycomb panel is made of alloy aluminium plate, stainless steel plate and other materials as the face and base plate, the middle is aluminium honeycomb core, high pressure composite into a honeycomb sandwich structure plate. With quality, high strength, good rigidity, sound insulation, heat insulation and other characteristics.

Overview

Marine aluminum honeycomb sandwich panels are widely used in the maritime industry due to their lightweight, high strength, and excellent corrosion resistance. These panels consist of two thin, high-strength aluminum sheets bonded to a core made of aluminum honeycomb. The structure provides exceptional rigidity and stability, making it ideal for various marine applications.

Key Features

Lightweight: The honeycomb structure significantly reduces the weight of the panel without compromising strength, leading to fuel savings and increased load capacity for marine vessels.

High Strength: The combination of aluminum sheets and honeycomb core provides high tensile and compressive strength, making the panels suitable for demanding marine environments.

Thermal and Acoustic Insulation: The honeycomb core can provide effective thermal and acoustic insulation, contributing to better energy efficiency and noise reduction on marine vessels.

Fire Resistance: Many marine aluminum honeycomb panels are designed to be fire-resistant, meeting stringent safety standards for marine applications.

Picture of Marine Aluminum Honeycomb Sandwich Panel