Marine Air Horn

The power source of the marine air horn is compressed air, controlled by a solenoid valve, and the air passes through the final piece of the spring whistle to emit a sound. There are two modes of operation: manual control and electric control.

Manual control: Use a manual pull cable to control the whistle sound. No power box, electric control box, or solenoid valve is required.

Electric control: Control the power button to make the whistle sound. It requires a power box, solenoid valve. 2 waterproof buttons and other accessories are equipped.

Overview

Products & detail

Working principle: 4 types of state, 2 types of operation

4 types of state

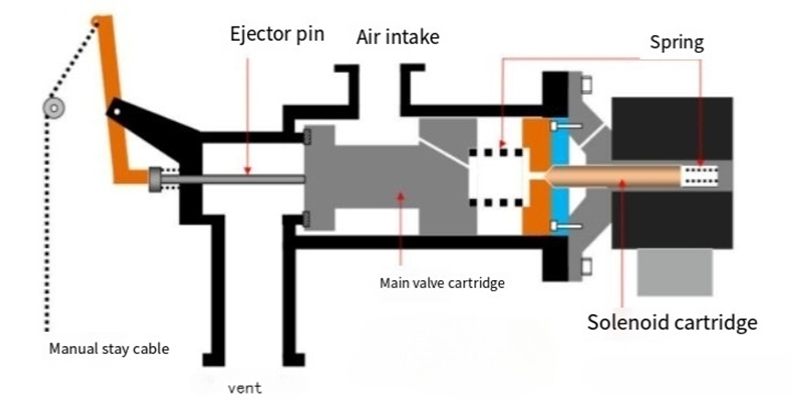

1. Natural gas-free state: When no gas enters the air inlet, the main valve core remains closed under the action of spring force; the solenoid valve core closes the spring chamber vent on the right side of the main valve core under the action of spring force on the right side.

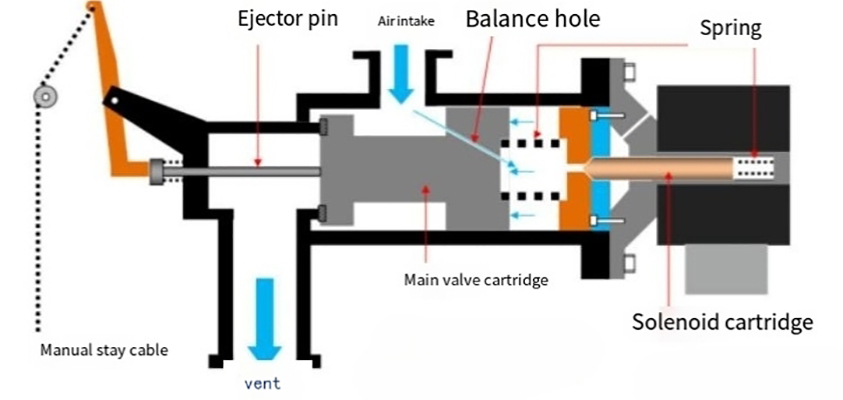

2. Ventilation is not working: When the air inlet is filled with air, in addition to the U-shaped space of the main valve core being filled with gas, the gas will enter the spring chamber on the right along the balance hole on the main valve core in the picture. When the spring chamber is filled with gas, since the force area on the right side of the main valve core is larger than the left side, according to the proportional relationship between the force and the area, the main valve core will be pointed to the left side between the gas force plus the spring force between the air inlet and the air outlet. channel. The solenoid valve core remains closed because the coil has no power.

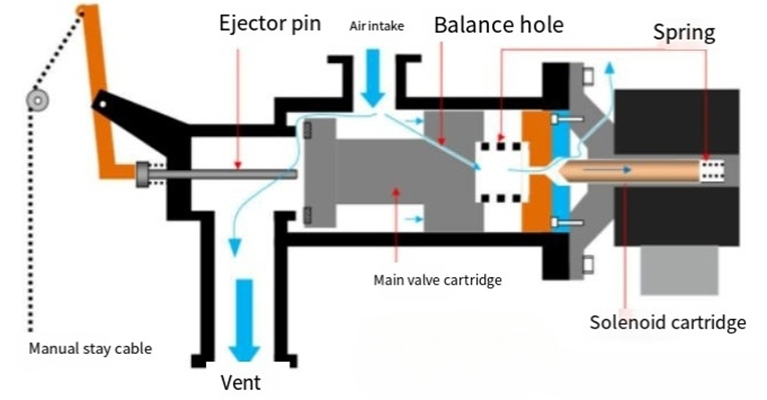

3. Electronically controlled whistle state: When the electric whistle control button is pressed in the cab, the solenoid valve core moves to the right under the action of magnetic force to open the vent hole in the spring chamber, and then the air in the spring chamber is released through the vent hole. Finally, it leaks into the atmosphere through the small hole on the solenoid valve body (the flow path is shown by the blue curved arrow in the figure). When the control air in the spring chamber on the right side of the main valve core is released, the main valve core will be pushed to the right by the gas force in the U-shaped chamber (much greater than the spring force), thus opening the channel between the inlet and outlet ( The gas flow path is shown by the curved arrow in the figure), and the air supply whistle sounds.

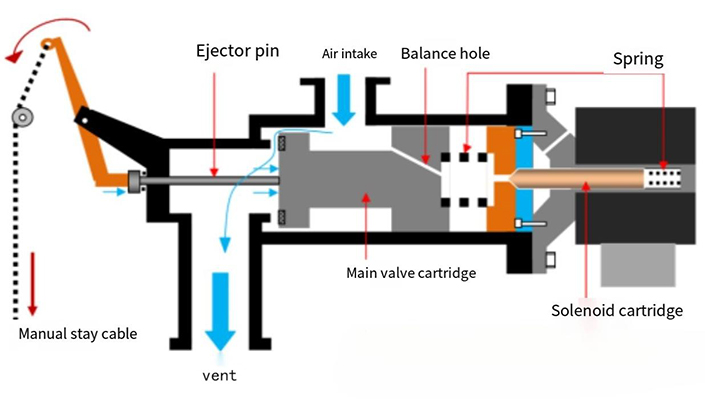

4. Manual whistle state: When the pull cable is manually pulled downward, the top of the control rod will be driven to push the top rod to the right. The push rod forcibly overcomes the gas force and spring force acting on the main valve core under manual force, opens the channel between the air inlet and the air outlet, and the air supply whistle sounds.

2 types of operation

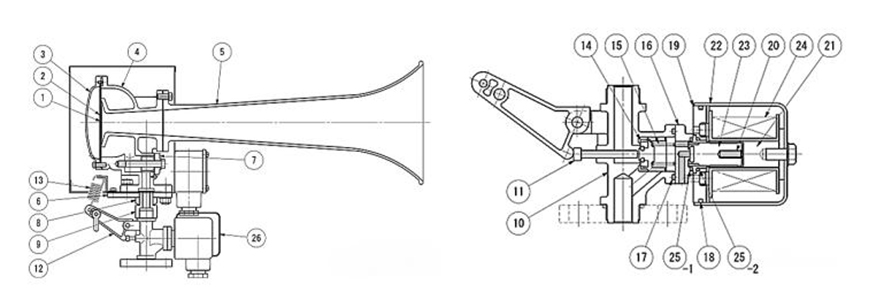

Manual operation is performed by using a pull rope in the cab. The valve push rod 11 is pressed down by the pull rod 12 pulled by the wire rope to open the main valve 14 and connect the air passage to the vibration plates 1 and 2.

Electric operation is to press the whistle button on the cab panel, the solenoid valve is energized, the plunger 23 is sucked to the right, the vent hole is opened, the air pressure on the right side of the main valve is released, and the main valve 14 moves to the right under the action of air pressure on the left Move and connect the air passage to vibrating plates 1 and 2. After releasing the button, the vent hole is closed, and the compressed air enters the right chamber from the left chamber through the balance hole on the main valve 14 until the pressures on both sides are balanced. side) and spring force, it is tightly closed and the air passage is closed.