Marine A30 Fire Damper

Marine A30 Fire Dampers usually have good sealing performance, which can prevent the spread of flames and smoke, and maintain a relatively safe environment inside the cabin. The installation location and method need to comply with relevant ship fire prevention regulations and standards to ensure maximum fire prevention in the event of a fire. Marine fire dampers play a crucial role in ship safety. They are important passage fire prevention facilities on ships, with high fire rating and fire resistance time, which can play a key role in fire isolation in the event of a fire, ensuring the safety of ships and crew.

Overview

Marine Condition Experiment

1. Tilt and Swing Test: Check if the product responds normally, manually and electrically closing is flexible and reliable.

2. Vibration test: whether it operates normally at hazardous frequencies.

3. Impact test: Can it be manually and electrically closed flexibly after impact.

4. Salt spray test: Check if the reactions of each mechanism are normal after the test.

5. Appearance inspection: Observe whether the appearance is smooth and flat.

6. Performance tests: insulation resistance test, voltage resistance test, control box sealing test, fire resistance limit test.

Main features:

1)Normally the damper is connected with the control power DC24V/AC220V/AC110V to start. Otherwise, the damper is closed.

2)Under the emergency situation, the control center can cut off the power and let the damper close automatically.

3) When the duct temperature reaches 70 ± 3 ℃, or when the outside temperature reaches duct 95 ℃, the temperature fuse is blown, cut off the power, the damper closed.

4) When the damper is closed or open, it can output signals.

5) The fire damper is provided with a complete electric control box which can control to open the damper remotely or nearby.

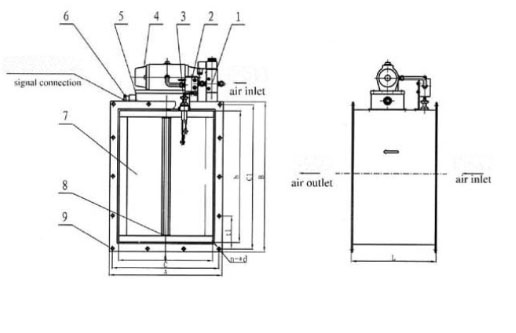

Drawing: