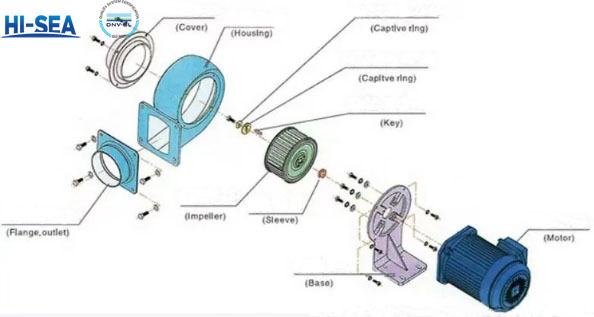

Main Components and Functions of Marine Centrifugal Fan

The Marine centrifugal fan generates centrifugal force by rotating the impeller, which accelerates the gas and sends it side by side. Its working principle is based on the principle that kinetic energy is converted into potential energy.

Overview

Structures and Functions:

Belt: It is used to connect the motor wheel and pulley to transmit power. There are only belt drives, and there are direct drive mechanisms without belts, pulleys and bearings.

Pulley: It is connected to the shaft through a key and plays a transmission role. Material: cast iron.

Shaft: one end is connected with the pulley, and the other end is connected with the impeller, which plays a transmission role. Carbon steel, finish turning and tempering.

Bearing: used to support the shaft (fan shaft) to prevent vibration from being directly applied to the motor.

Shock absorber (cushion): reduce vibration, reduce noise and prolong service life. The driving device and motor of each fan should be connected to the fan body evenly through the shock absorber, thus prolonging the life of the driving device and impeller and making the operation quieter.

Flooding cap: it is buckled on the floodwater to facilitate installation and prevent rainwater from leaking into the room.

Motor: provides power for the fan. It is the main part of the fan.

Return air check valve: to prevent wind from flowing backwards into the room. There are two kinds of check valves: gravity check valve and electric check valve.

Impeller: the key component to drive gas flow. There are many forms, such as axial flow, forward bending centrifugation, backward tilting centrifugation, backward bending centrifugation, mixed flow and so on.