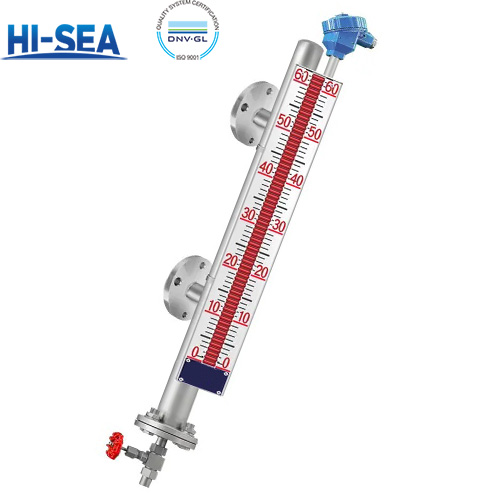

Magnetic Float Level Gauges

Process Connection: Flanged, 2" ANSI 150

Float Density: 0.6 g/cm³

Temperature Range: -40°C to +150°C

Pressure Range: Vacuum to 25 bar

Indicator Type: Magnetic Flap Indicator

Output Signals: 4-20 mA

Installation Orientation: Vertical

Overview

Magnetic Float Level Gauge Working Principle

A magnetic float level gauge is a non-intrusive, reliable instrument widely used to measure and indicate the liquid level in tanks, vessels, or reservoirs. Its core design leverages the magnetic coupling effect (magnetic attraction/repulsion) to translate the vertical movement of a float (driven by liquid level changes) into a visible or measurable level reading.

Core Components

To understand the working principle, first identify the 4 essential parts that enable its operation:

Component | Function |

Float | A buoyant device (made of corrosion-resistant materials like stainless steel, PTFE) that floats on the liquid surface. It contains a permanent magnet (e.g., neodymium) inside. |

Guiding Tube (Float Chamber) | A vertical, sealed tube mounted inside or outside the vessel. It guides the float to move only vertically (prevents rotation or lateral displacement) and protects the float from liquid turbulence. |

Magnetic Indicator Strip | A horizontal strip (installed on the outer wall of the guiding tube or vessel) composed of small, independent bi-color magnetic flip discs (e.g., red/white or black/yellow). Each disc is a lightweight, magnetically sensitive element. |

Optional Transmitter | A sensor (e.g., Hall effect sensor, reed switch) integrated with the indicator strip. It converts magnetic signals into electrical signals (4-20mA current or digital output) for remote monitoring/control. |