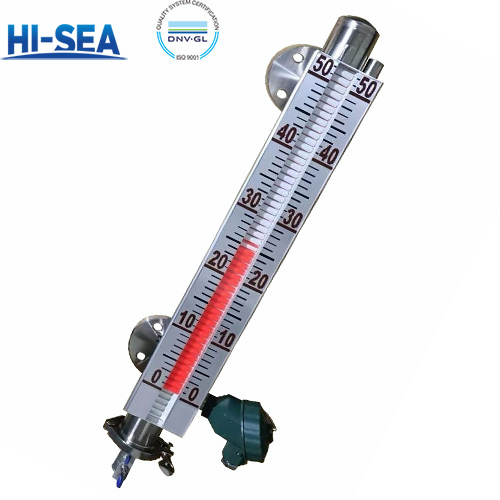

Magnetic Float Level Gauge

Application Scenarios

• Industrial Tank Monitoring: In the petrochemical industry, it is used for storage tanks of crude oil and acid - base solutions. In the energy and power industry, it is used for the liquid - level measurement of boiler drums and desulfurization towers in high - temperature and high - pressure working conditions.

• Special Working Conditions: For underground storage tanks, UPVC - material magnetic float level gauges are resistant to groundwater corrosion. They are also suitable for closed systems such as liquefied gas storage tanks and vacuum reaction kettles.

Overview

A Magnetic Float Level Gauge is a mechanical liquid level measurement instrument that operates based on the principles of a communicating vessel and magnetic coupling. It is also known as a magnetic flap level gauge.

Working Principle

• Communicating Vessel Principle: The main body of the instrument is connected to the side wall of the container through a flange, forming a U-shaped communicating structure. This ensures that the liquid level in the main body is always the same as that in the container.

• Magnetic Coupling Transmission: The float unit contains a magnetic float, usually a stainless - steel sealed structure, with a density slightly lower than that of the measured medium. As the liquid level rises or falls, the float moves up and down accordingly. The magnetic field of the float drives the two - color magnetic flip columns (red/white) in the external flip - plate box to flip. The flip - column at the liquid level shows red, clearly marking the real - time liquid level height.

• Remote Transmission Mechanism: Through a magnetic switch or a magnetostrictive rod, the position of the float is converted into a 4 - 20mA current signal or a switching value, enabling remote monitoring and alarming.

Advantages

• Intuitive and Reliable: The mechanical flip - plate does not depend on a power source, and the red - white boundary is clear. It is suitable for explosion - proof, high - temperature (-20°C - 450°C), and high - pressure (≤32MPa) environments.

• Strong Adaptability: It has strong corrosion resistance. Materials such as PVC or PTFE - lined are suitable for strong - corrosion media like hydrofluoric acid. It is also compatible with vacuum conditions and can be used for liquid - level monitoring in closed tanks and vacuum tanks.

• Low - Cost and Easy to Maintain: Its price is only about half of that of a radar level gauge, and it has no complex circuits, resulting in a long cleaning cycle.